|

| Raspberry Pi interface to the RFM12B radio module, with integrated ISP programmer. The cut-out is to enable the PCB to fit inside the Multicomp Raspberry Pi case. |

Current status

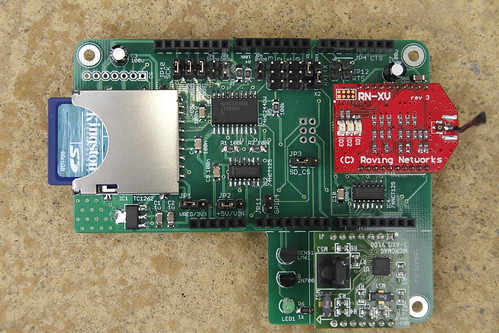

Earlier in the year I posted a design for a

wireless gateway for the Raspberry Pi. It featured interfaces for the Hope RFM12 and XBee (or Ciseco XRF) radio modules. Also included was an in-circuit serial programming (ISP) programming interface for Atmel microcontrollers. I later

refined the ISP interface to include some protection for the Raspberry Pi by adding a buffer and FET switch. I have not yet tried accessing the RFM12B directly from the Pi but other people have had

problems, mainly it seems because of the time-critical interrupt handling. I'm sure this problem will eventually be solved once the

Eve Alpha boards become widely available.

Martin Harizanov solved this problem by adding an Atmel ATtiny microcontroller to bridge between the UART interface on the Pi and the SPI interface on the RFM12B. I bought a bare PCB that did this from the

Open Energy Monitor shop. I tested the RFM12Pi Raspberry Pi Expansion board communicating with one of my

Calunium v2 development boards, everything worked. Martin chose the ATtiny84 microcontroller which has just 512 bytes of RAM. I would like to have a solution which more closely mimics the Ciseco XRF module that I am currently using, which has a 240 byte buffer. One reason for needing a larger buffer is that the radio protocol I am using supports over the air firmware updates, with the new firmware sent in 128 byte blocks. If I am to implement something with 240 byte transmit and receive buffers I will need a microcontroller with more than 512 bytes of RAM.

Preliminary design

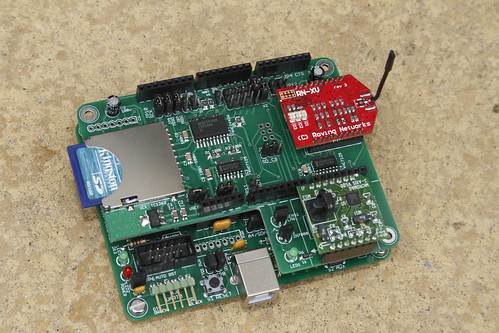

Based on my previous work and inspired by

Martin Harizanov's implementation I have designed a RFM12B shield for the Raspberry Pi with integrated ISP interface. The microcontroller on this board is the popular ATmega328P, as used in the

Arduino. Including the ISP interface has considerably increased the size of the PCB but this is a price I am willing to pay. The board is intended to be used as part of the

AuroraWatchNet magnetometer network and the ability to remotely update the firmware will be very useful, especially since I can already perform over-the-air firmware upgrades on the battery-powered Calunium node. Surface-mount passive components could be used to reduce the PCB size but this would be contrary to my goal of making the AuroraWatchNet magnetometers easy to build for novice constructors.

The 74LVC244 buffer has two 4-bit line drivers, allowing two independent ISP interfaces to be included. The first is for the on-board ATmega328P microcontroller, the second is wired to a standard Atmel ISP header to allow an external microcontroller to be programmed. It means that the ATmega1284P used in the remote Calunium of the AuroraWatchNet magnetometers can be programmed initially, or recovered in the case of an over-the-air firmware upgrade mistake.

I hope to have some circuit boards made in January 2013 so if you spot any mistakes please let me know as soon as possible!

Open source

The Eagle PCB design files for the RFM12B/ISP shield for Raspberry Pi are available on

Github and are licensed under the

Creative Commons Attribution-ShareAlike 3.0 Unported License.