This is part of a series of short tutorials on advanced topics of using Kicad, the favorite schematic/PCB design software here at Wayne and Layne.

Once you’ve finished working on your PCB and are ready to send it off for fabrication, one step remains: “Plotting” the PCB design to Gerber files. The Gerber file format is a very old format with its roots in the 1960s, and is used to completely describe a single layer of a PCB design. You need to generate one gerber file per layer of your PCB design (Copper, SolderMask, and SilkScreen, for both the top and bottom sides, plus the PCB Edges layer). The information about where the holes are drilled, and what size the hole should be, are stored in a separate file with a different format, called the Excellon format, named after the market leader in CNC drilling machines during the 1980s.

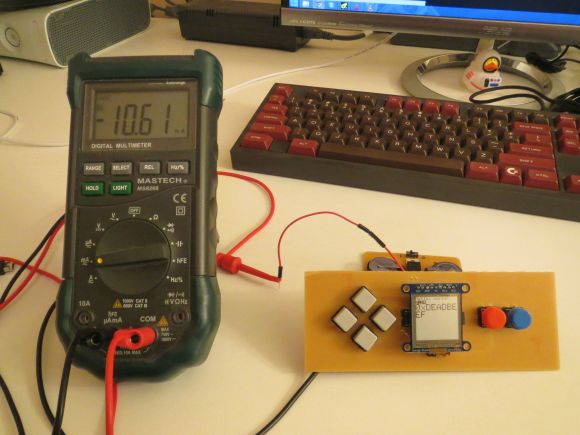

To generate the gerber and drill files for production, click on the Plot toolbar button in PCBNEW. It is located in the top toolbar and looks like a printer with a “P” overlaid. This brings up the plot dialog box. (Click to enlarge image.)

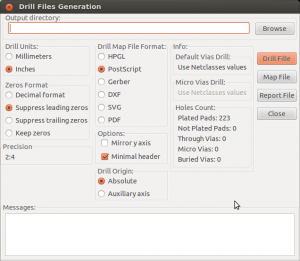

Here, ensure that the “Plot format” is “Gerber”. Leave the “Output directory” field blank, and it will default to saving the files into the project directory. Make sure you check all the layers you want to send to production. If you didn’t use back-side silkscreen, or don’t want to use any back-side silkscreen (some places charge extra for that), you can un-check the B.SilkS layer. The other checkmark boxes are the defaults, but ensure that “Exclude PCB edge layer from other layers” and “Use proper filename extensions” are checked. Press “Plot” to generate the files, one per layer. You will see output in the “Messages:” box at the bottom. When that is finished, click “Generate Drill File” to bring up the next dialog box. (Click to enlarge image.)

Again, leave the “Output directory” text field empty. The settings here are very important, especially the Drill Units (Inches), Zeros Format (Suppress leading zeros), and Options (Minimal header). You absolutely must check “Minimal header” and un-check “Mirror Y-Axis”. Since we aren’t making a drill map, the “Drill Map File Format” option doesn’t matter. Click the “Drill File” button to generate the drill file. Then press “Close” and “Close”.

Now you can zip up the generated gerber/drill files and send them off for fabrication. At Wayne and Layne, we really like the prototype PCB fabrication services from OSH Park. They describe themselves as

This is a community printed circuit board (PCB) order. We take designs from lots of people, put them all together on a panel and then order the panel from a fab. Since we’re all splitting the panel setup cost, this lets us make circuit boards inexpensively.

This service grew out of the DorkbotPDX PCB Order run by @laen and now comprises of a two-layer panel every other day, a four-layer panel every three weeks and a periodic two-layer medium run service for people needing more than 150 square inches of board.

They have very inexpensive rates, decent production time, and very high-quality output. Plus, the gold and purple boards just look very nice! Here are the details about pricing and design rules (minimum clearance and trace width, minimum hole size, etc).

Other tutorials in this series:

Several years ago, Chris Gregg, a Tufts University lecturer and computer engineer, received a letter from his friend Erica. This wouldn’t be so unusual, except that it was typed on an actual typewriter, not a printer. Gregg is a fan of vintage typewriters, but, as with myself, makes many mistakes, […]

Several years ago, Chris Gregg, a Tufts University lecturer and computer engineer, received a letter from his friend Erica. This wouldn’t be so unusual, except that it was typed on an actual typewriter, not a printer. Gregg is a fan of vintage typewriters, but, as with myself, makes many mistakes, […]