02

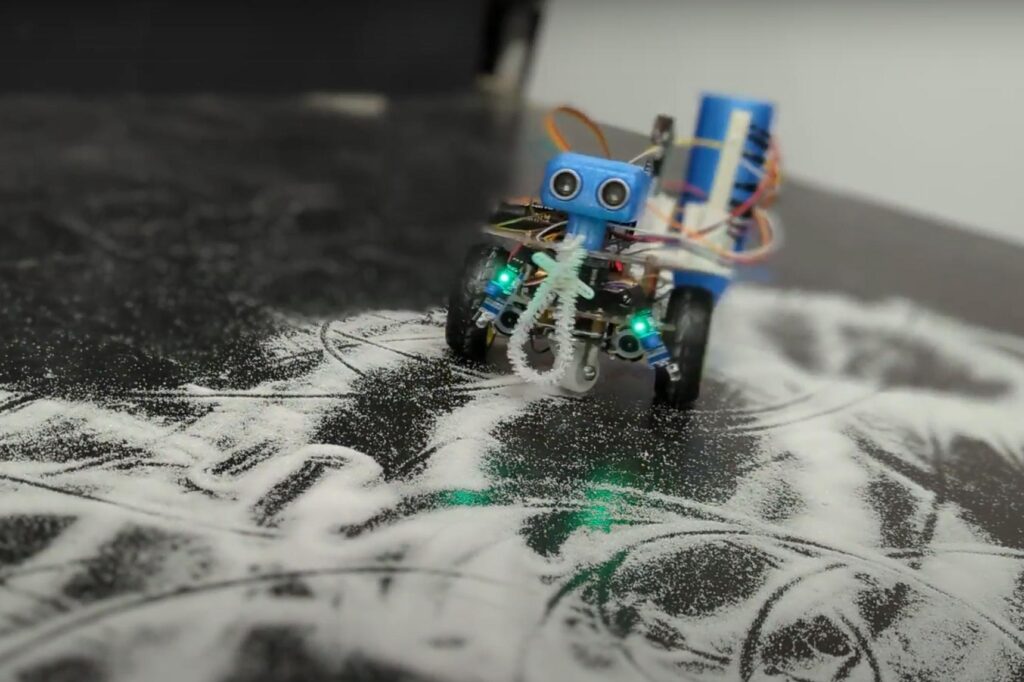

The future we were promised was supposed to include robot maids and flying cars. The future we got has Roomba vacuums and Southwest Airlines. But at least those Roomba vacuum robots work pretty well for keeping floors slightly cleaner. Sadly, they leave elevated surfaces untouched and dust-ridden. To address that limitation, Jared Dilley built this tiny DIY Roomba to clean his desk.

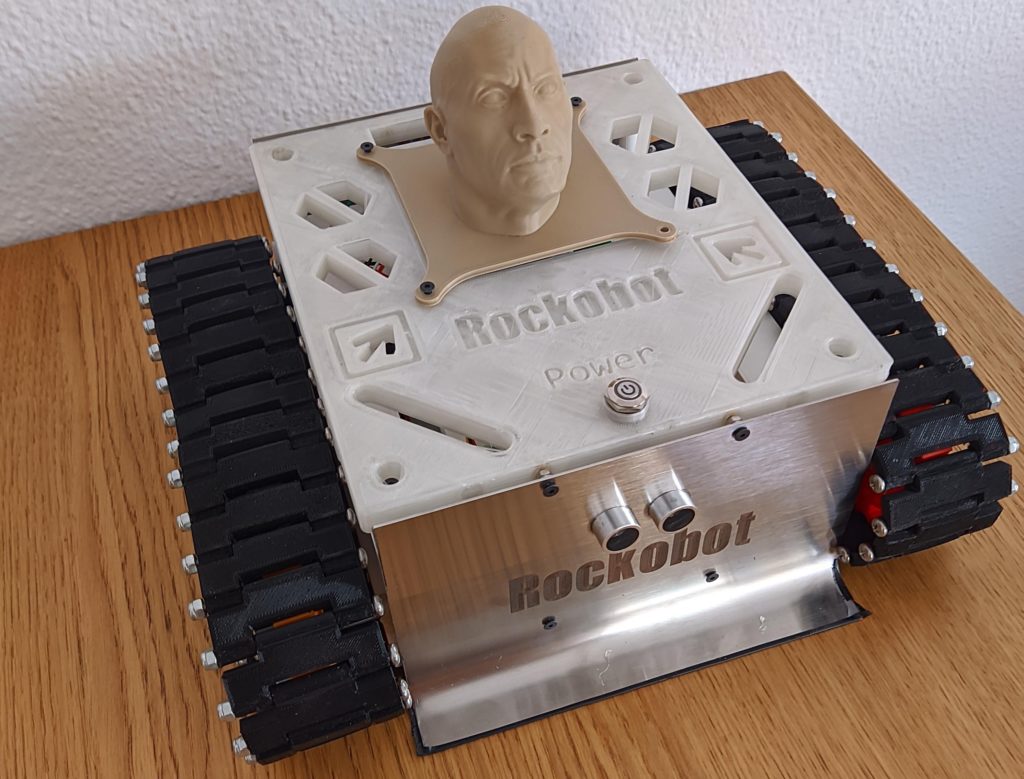

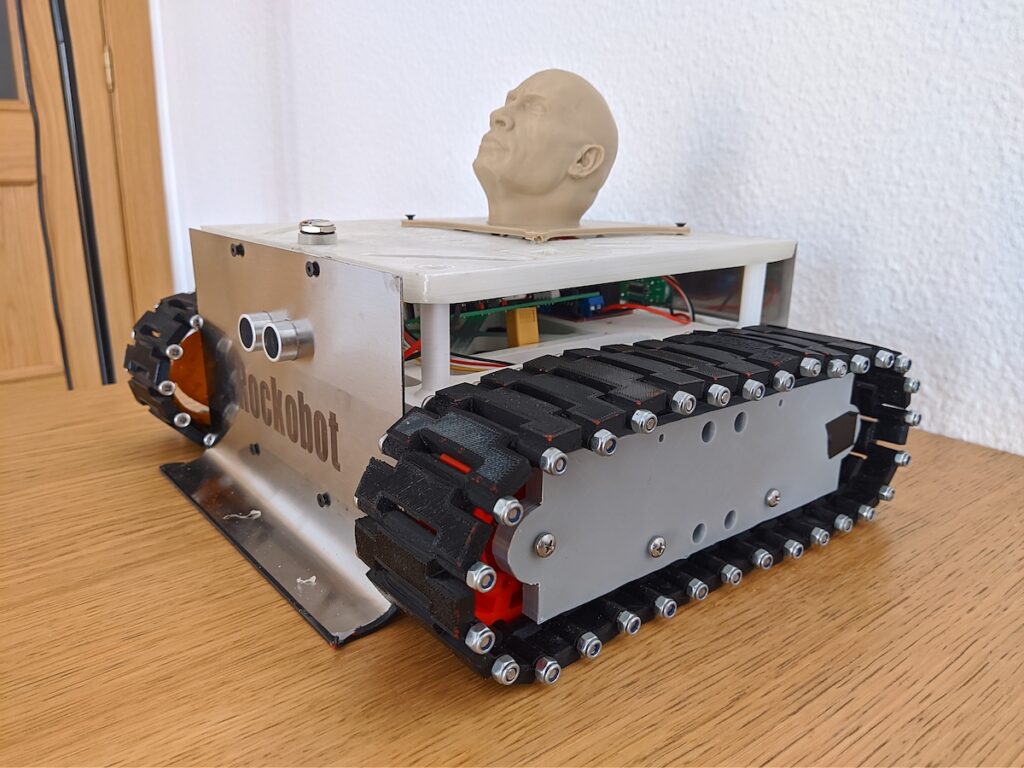

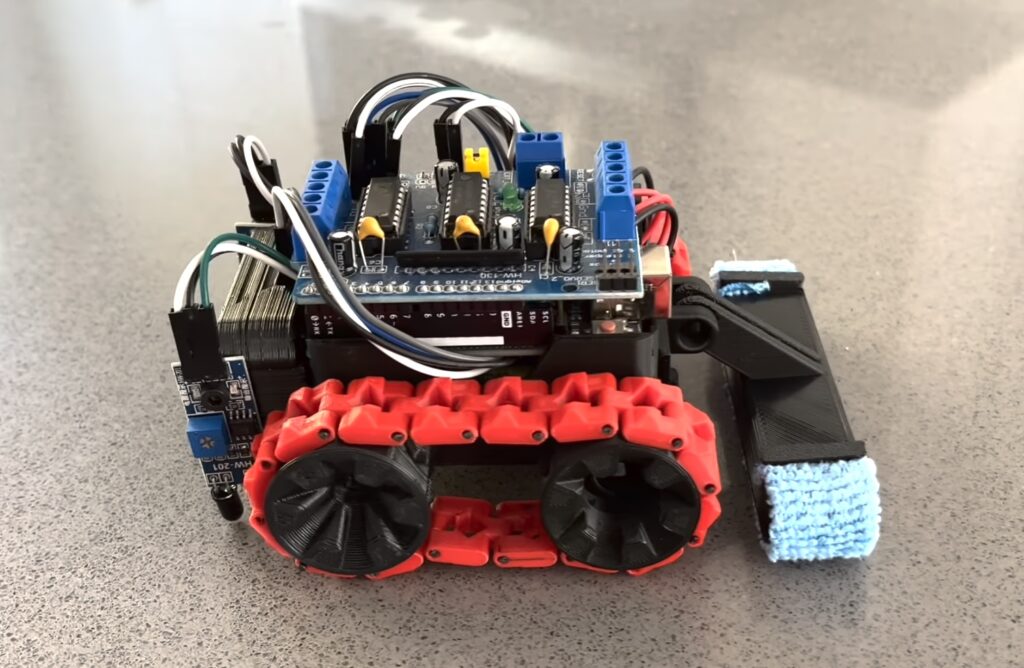

Dilley is a dog owner and so his desk ends up with quite a bit of dust and loose hair, even though his dog is large and doesn’t sit on the desk—a mystery all pet owners will find relatable. Fortunately, Dilley is an engineer and had already created a small Arduino-controlled tank robot a while back. That operated a bit like a Roomba and would drive around until its ultrasonic sensor detected an obstacle, at which point it would turn. Dilley just needed to repurpose that robot into small mean cleaning machine.

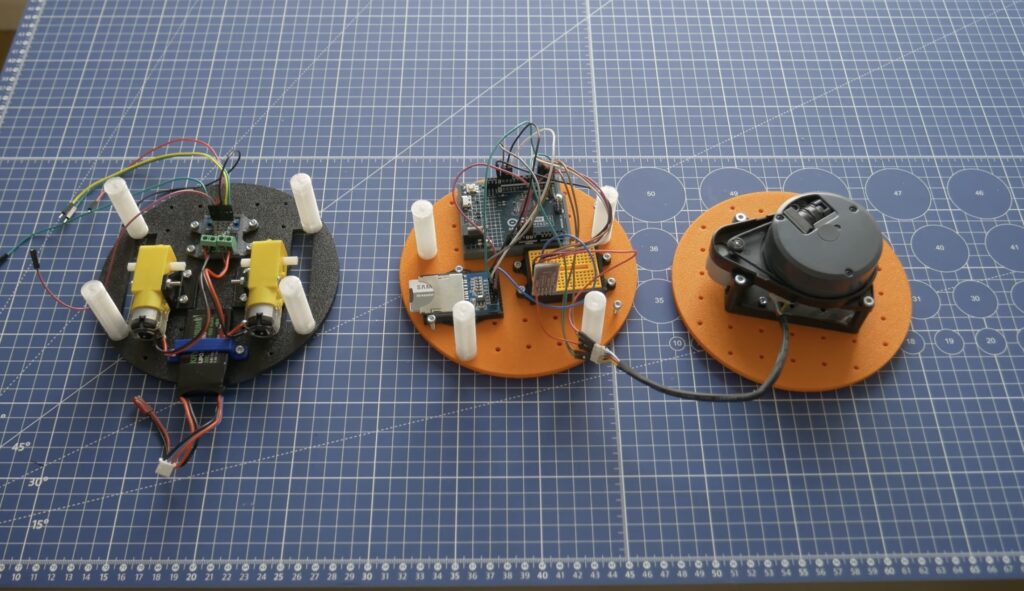

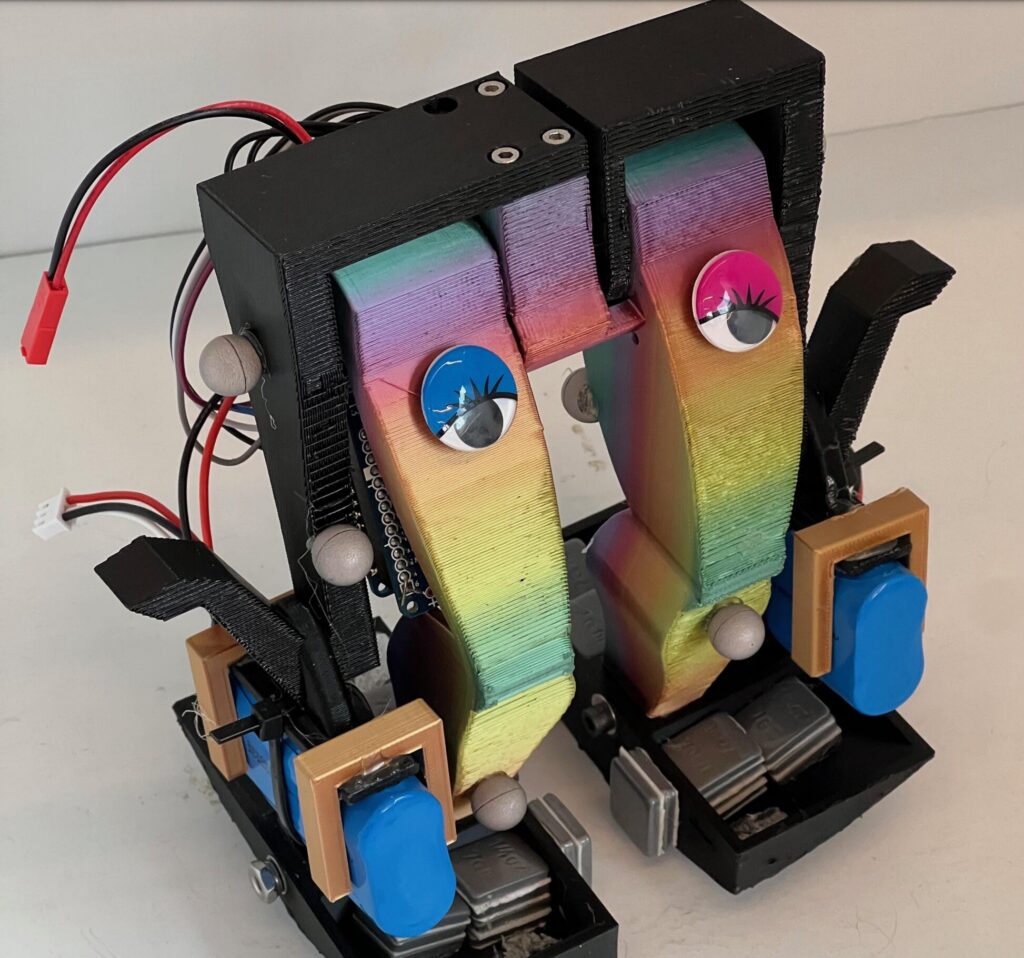

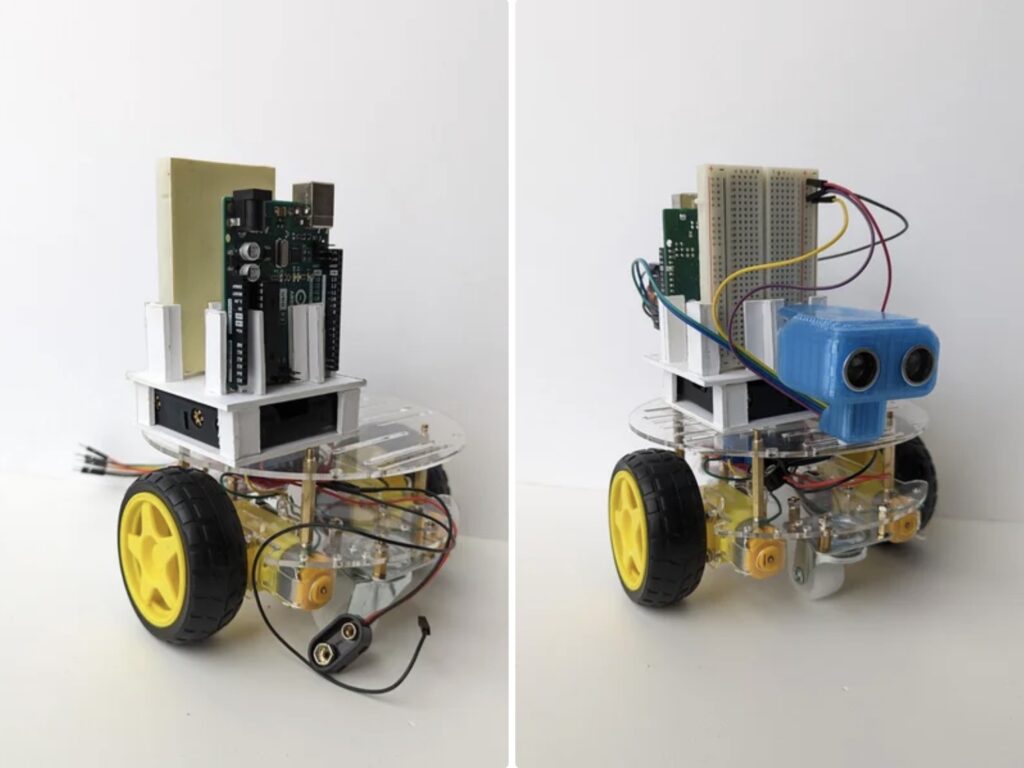

The 3D-printed robot operates under the control of an Arduino UNO Rev3 through a motor driver shield. Originally, it only had the ultrasonic sensor, which was enough to detect obstacles in front of the robot. But because its new job is to patrol desks and countertops, Dilley had to add “cliff” sensors to keep it from falling off. He chose to put an infrared sensor at each of the front two corners. The Arduino will register the lack of a reflection when one of those sensors goes past an edge, and will then change course. A Swiffer-like attachment on the back of the robot wipes up dust and dog hair.

The post Tiny DIY Roomba cleans desks and countertops appeared first on Arduino Blog.