09

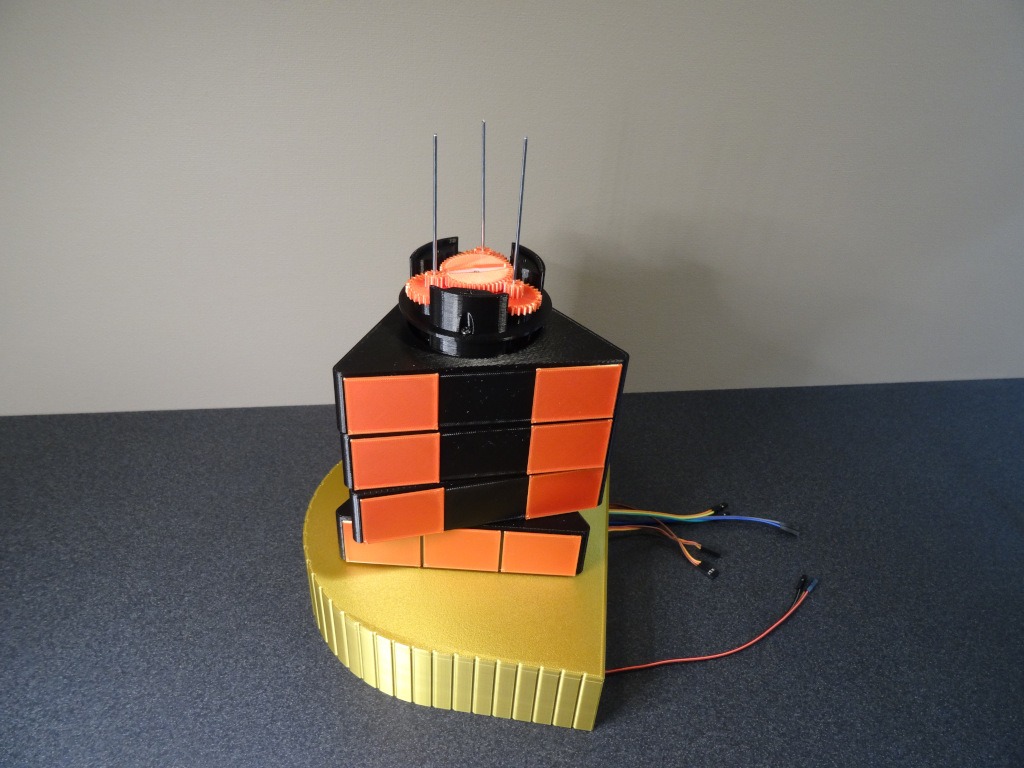

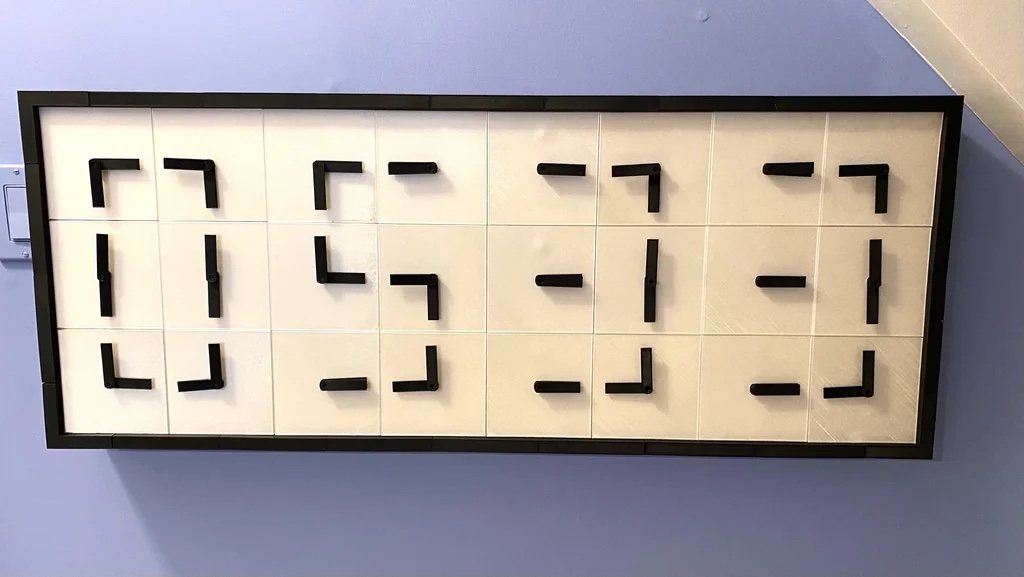

Back in April 2021, Instructables user saulemmetquinn had the idea to build a fully 3D-printed clock that was based on the Triangulum constellation, which as the name implies, is a triangle. But it wouldn’t only tell the time using the typical set of hands and numbers, but also the current phase of the moon to stick with the astronomical theme.

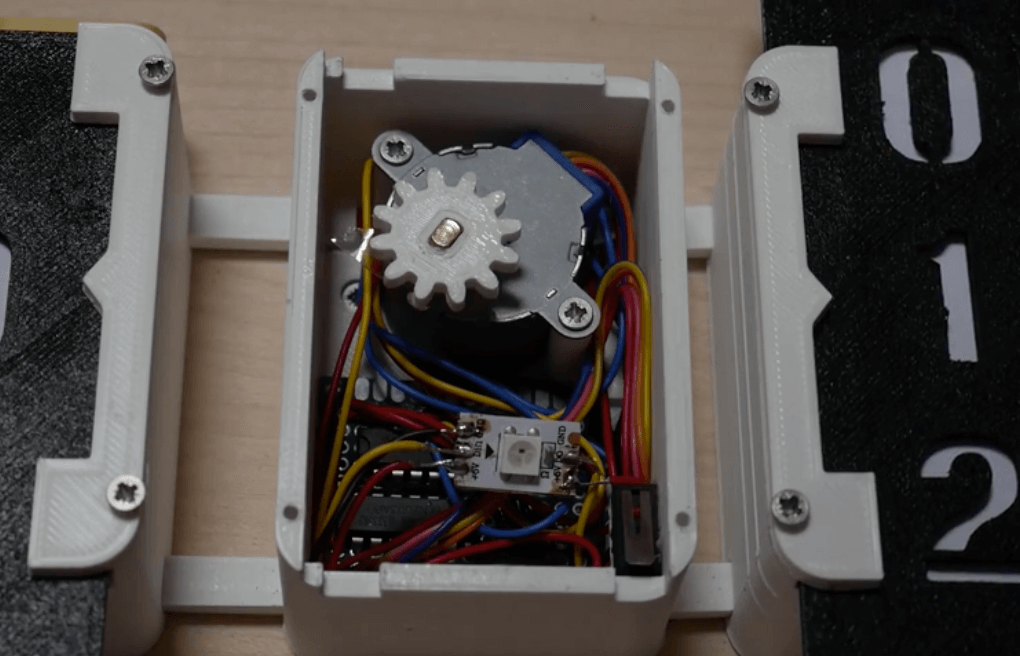

To begin, Saul made a detailed mechanical model in CAD, complete with every facet and gear necessary for it to run. In short, the clock contains a spinning stepper motor that completes one rotation every 15 seconds (a ratio of 1:15). When combined with a series of reduction gears, this rate slows all the way down to 1:43200 for a single hour. In addition to the second, minute, and hour hands, an extra set of gears were added with a collective ratio of 99:2924 that keep track of the current moon phase.

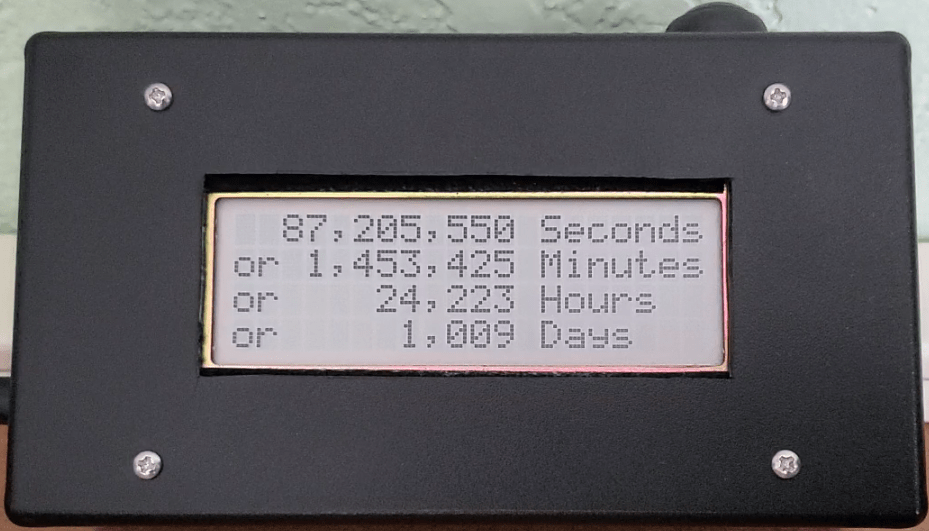

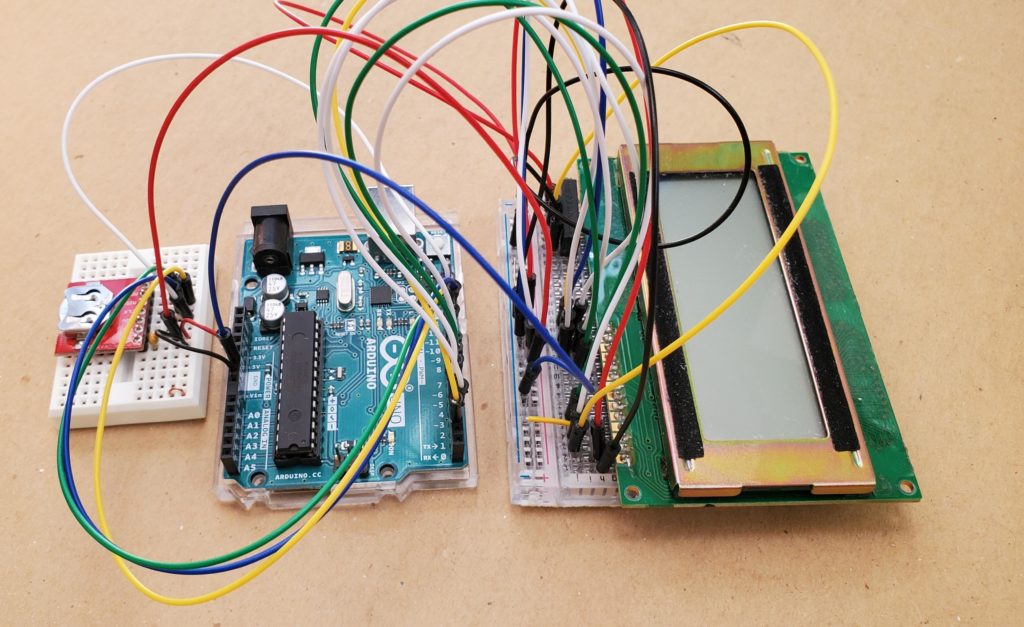

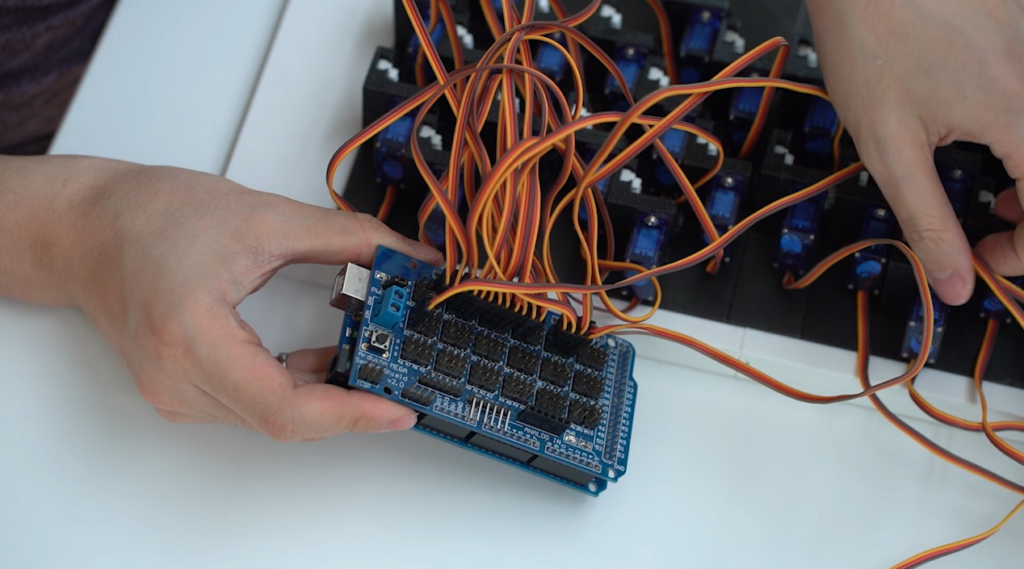

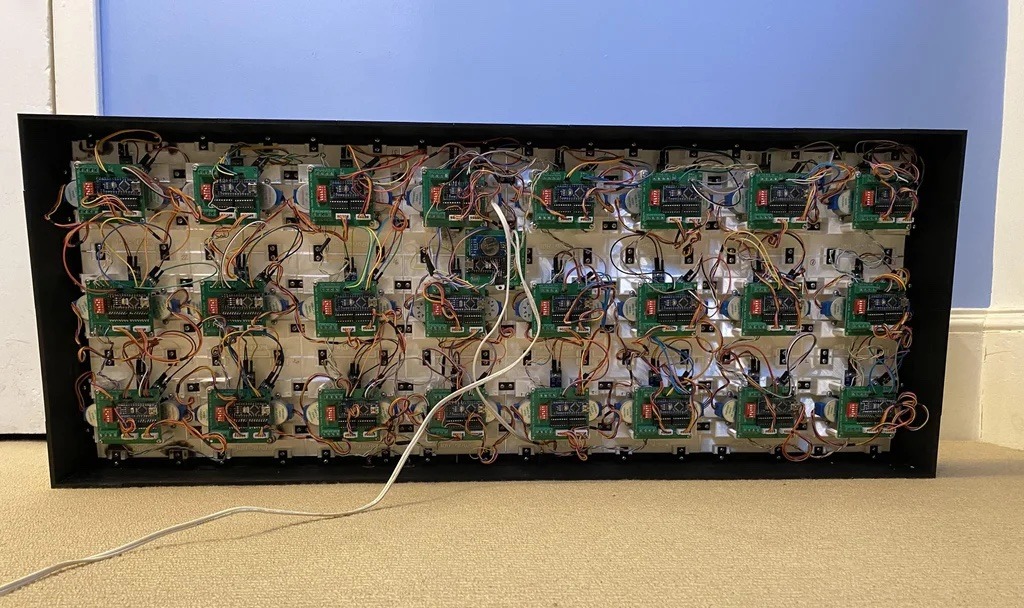

After carefully assembling the clock by hand after printing each part, the ubiquitous ULN2003 stepper motor driver and 5V 28BYJ-48 were added to an inner panel along with an Arduino Nano Every. This board was selected due to its small size and larger memory footprint, which made running the Holo Clock firmware simple.

To read more about this project, you can visit Saul’s write-up here on Instructables.

The post This 3D-printed, three-sided clock tells time with three hands appeared first on Arduino Blog.