24

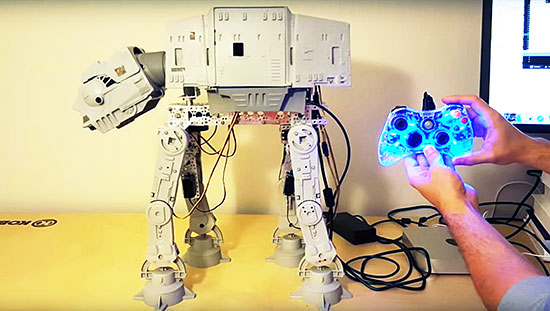

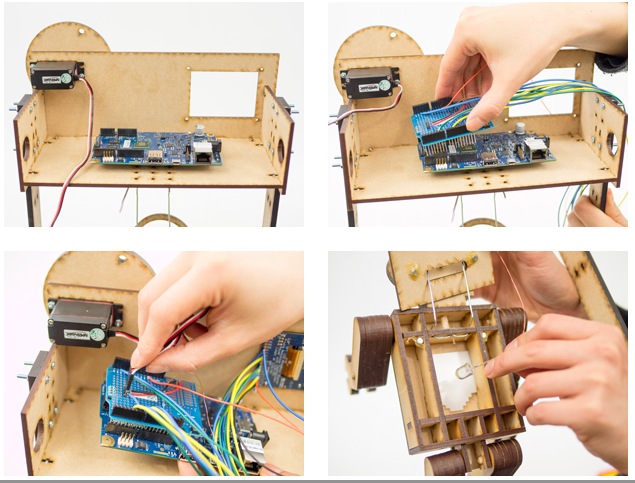

First the robots took our jobs, then they came for our video games. This dystopian future is brought to you by [Little French Kev] who designed this adorable 3D-printed robot arm to interface with an Xbox One controller joystick. He shows it off in the video after the break, controlling a ball-balancing physics demonstration written in Unity.

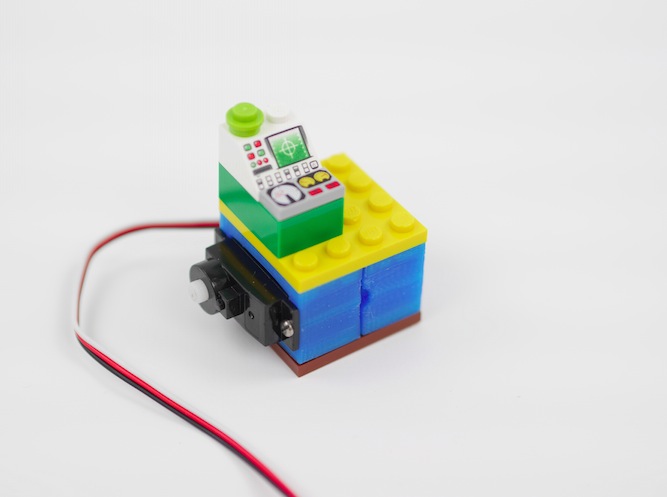

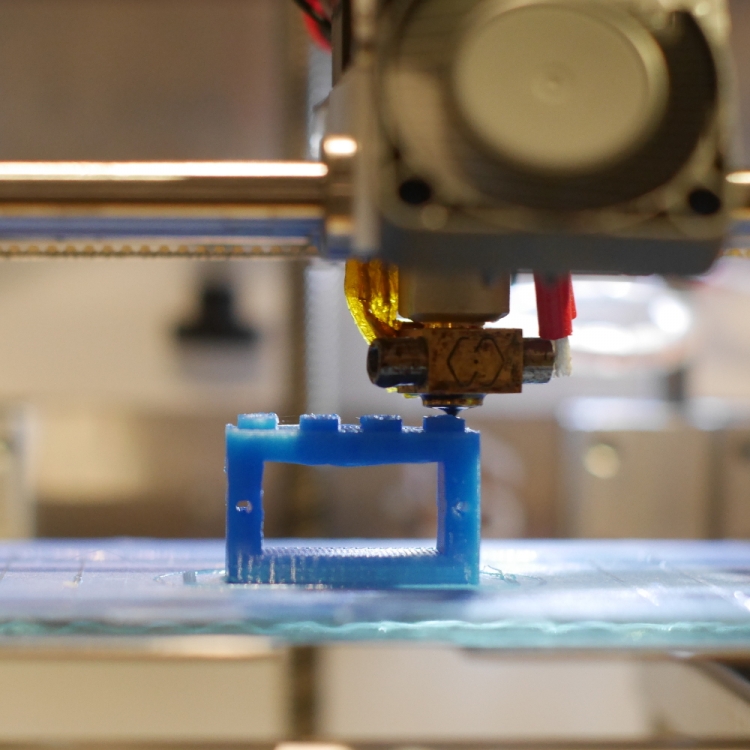

Hats off to him on the quality of the design. There are two parts that nestle the knob of the thumbstick from either side. He mates those pieces with each other using screws, firmly hugging the stick. Bearings are used at the joints for smooth action of the two servo motors that control the arm. The base of the robotic appendage is zip-tied to the controller itself.

The build targets experimentation with machine learning. Since the computer can control the arm via an Arduino, and the computer has access to metrics of what’s happening in the virtual environment, it’s a perfect for training a neural network. Are you thinking what we’re thinking? This is the beginning of hardware speed-running your favorite video games like [SethBling] did for Super Mario World half a decade ago. It will be more impressive since this would be done by automating the mechanical bit of the controller rather than operating purely in the software realm. You’ll just need to do your own hack to implement button control.