25

3D printers need to set their hot ends to a very specific temperatures suited to the filament material and keep them at those temperatures throughout the printing process. Most use PID (Proportional-Integral-Derivative) control for that purpose, which modulates power according to an algorithm that prioritizes stability and prevents feedback oscillations. But what if you want to control a hot end that isn’t connected to a 3D printer? In that case, Michael Klements has a guide on how to build a dedicated hot end controller.

This dedicated hot end controller is useful if you’re building something like a filament extruder. Klements designed it for the PET Bottle Recycler, which turns garbage into useful filament. That machine needs to melt down the plastic and, naturally, it uses a hot end to do so. But because it isn’t connected to a 3D printer, Klements needed some way to control the temperature of the hot end. A full 3D printer controller board would have been overkill, so he created this dedicated controller for the job.

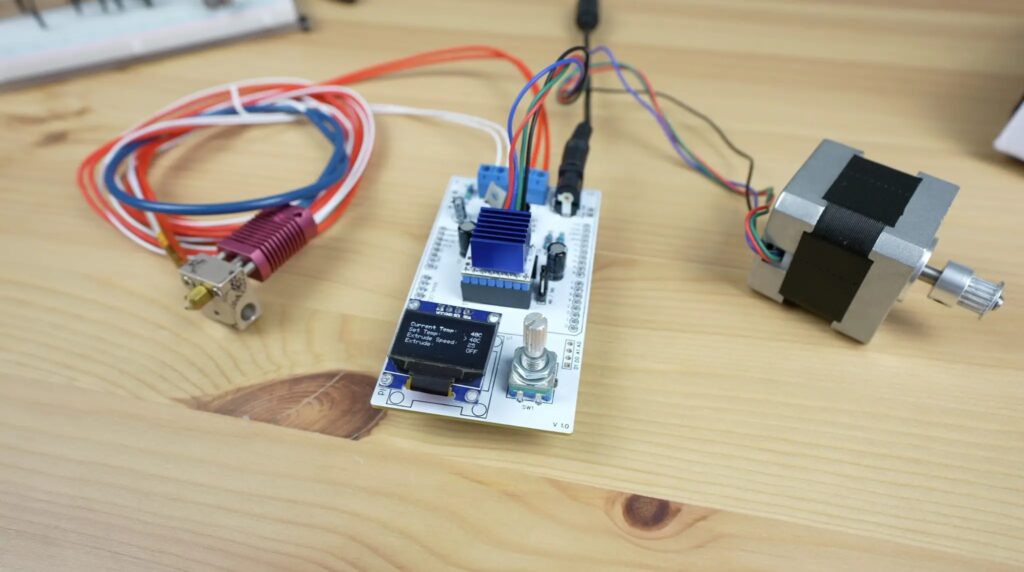

Because Klements designed this for the PET Bottle Recycler, it includes a stepper motor driver as well. It is meant for use with a Creality Ender 3 hot end, but should work with others that have standard thermistor feedback (which is crucial for PID control). The custom PCB hosts an Arduino UNO R4 WiFi, which is brand new and has a lot of great features like a built-in LED matrix. That PCB also contains a MOSFET to control power to the hot end, a small OLED screen, and a rotary push button for navigating the menu.

After assembling the PCB and flashing the provided sketch, you’ll be able to directly control a hot end or a complete filament extruder like the PET Bottle Recycler.

The post Building a dedicated 3D printer hot end controller with the Arduino UNO R4 WiFi appeared first on Arduino Blog.

This project goes a little beyond simple Arduino programming though. A 12V to 5V power supply drives the device, which is laid out on a blank PCB. The display fits snugly over the circuit which reduces the footprint of the project, and the entire thing is housed in a custom-printed case with a custom-printed pushbutton. The device gets power and data over the RJ45 connection so no external power is needed. If you want to take a look at the code,

This project goes a little beyond simple Arduino programming though. A 12V to 5V power supply drives the device, which is laid out on a blank PCB. The display fits snugly over the circuit which reduces the footprint of the project, and the entire thing is housed in a custom-printed case with a custom-printed pushbutton. The device gets power and data over the RJ45 connection so no external power is needed. If you want to take a look at the code,