SyRen 10A Regenerative Motor Driver

We have added some new products from Dimension Engineering to the Arduino Fun Shop. We are offering a 25% Discount Coupon, good Friday – Monday on these products! Use coupon code BFCM09 when completing your shopping cart order.

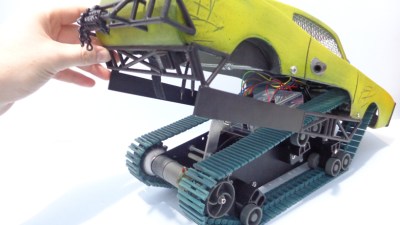

The SyRen motor driver is one of the most versatile, efficient and easy to use motor drivers on the market. It is suitable for medium powered robots – up to 30lbs in combat or 100lbs for general purpose robotics.

With just one SyRen driver you can control a motor with: analog voltage, radio control, serial and packetized serial. You can build many different robots of increasing complexity for years to come with a SyRen. Owning two SyRens allows you to build differential drive (tank style) robots because they can work in tandem with built in mixing.

The operating mode is set with the onboard DIP switches so there are no jumpers to lose. The SyRen features screw terminal connectors – making it possible for you to build a robot without even soldering.

SyRen is the first synchronous regenerative motor driver in its class. The regenerative topology means that your batteries get recharged whenever you command your robot to slow down or reverse. SyRen also allows you to make very fast stops and reverses – giving your robot a quick and nimble edge.

Buffered 2g Accelerometer

The DE-ACCM2G is an off the shelf 2 axis 2g accelerometer solution with analog outputs. It features integrated op amp buffers for direct connection to a microcontroller’s analog inputs, or for driving heavier loads.

To maximise usability, it is designed to fit in the DIP-14 form factor, making the DE-ACCM2G suitable for breadboarding, perfboarding, and insertion into standard chip sockets. To keep things as simple as possible, there are only 4 pins – two for power, and two for the X and Y analog outputs.

Additional circuitry ensures that the product won’t be damaged by reversed power connections, and it has an onboard voltage regulator to allow operation from a wide range of inputs.

5V 1A Switching Voltage Regulator

The DE-SW0XX family of switch mode voltage regulators are designed to be the easiest possible way to add the benefits of switch-mode power to a new or existing project. A DE-SW050 will allow you to take a higher voltage and it step down a 5V output in a compact, efficient manner. The DE-SW0XX family is pin-compatible with the common 78XX family of linear voltage regulators. They have integrated decoupling capacitors, so external capacitors are not generally necessary.

What is wrong with a linear regulator?

Linear regulators are great for powering very low powered devices. They are easy to use and cheap, and therefore are very popular. However, due to the way they work, they are extremely inefficient.

How is a switching regulator better?

A switching regulator works by taking small chunks of energy, bit by bit, from the input voltage source, and moving them to the output. This is accomplished with the help of an electrical switch and a controller which regulates the rate at which energy is transferred to the output (hence the term “switching regulator”).

The energy losses involved in moving chunks of energy around in this way are relatively small, and the result is that a switching regulator can typically have 85% efficiency. Since their efficiency is less dependent on input voltage, they can power useful loads from higher voltage sources.

Switch-mode regulators are used in devices like portable phones, video game platforms, robots, digital cameras, and your computer.

AnyVolt 3

The AnyVolt 3 Universal DC-DC Converter is an adjustable step up / step down 3A switching regulator. The output is adjustable from 3 to 24V. The output voltage is set with a small screw potentiometer on the back of the AnyVolt 3. Once the output voltage is set, it does not matter whether input voltage is higher, lower, or the same as the desired output. The potential applications are endless and only limited by the unit’s specifications and your collection of gadgets that require DC power at a different voltage than their supply.

Input power and output loads are connected with reusable screw terminals, so no soldering is necessary.