25

The cost of a new prosthetic arm can range from several thousand dollars to tens of thousands, putting them out of reach for many people. Ahmad Ikram recognized this need and decided to design and build a far cheaper, open source version that has myoelectric capabilities.

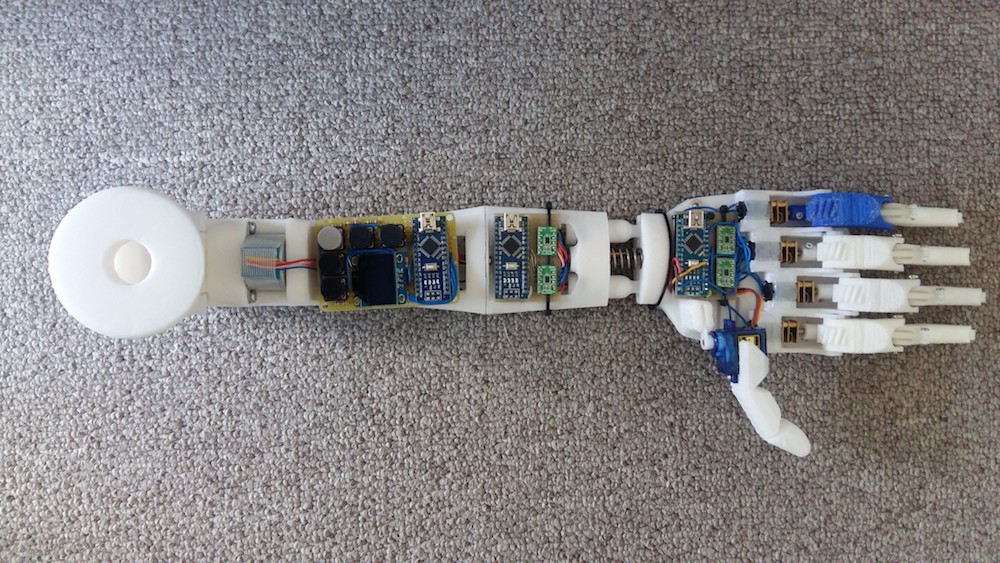

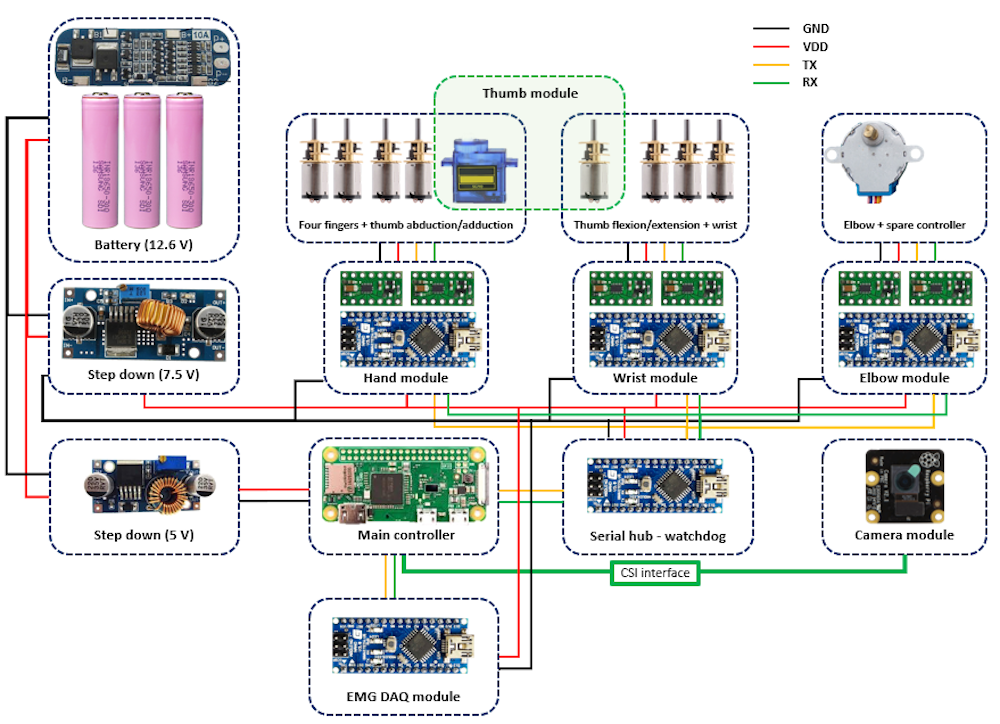

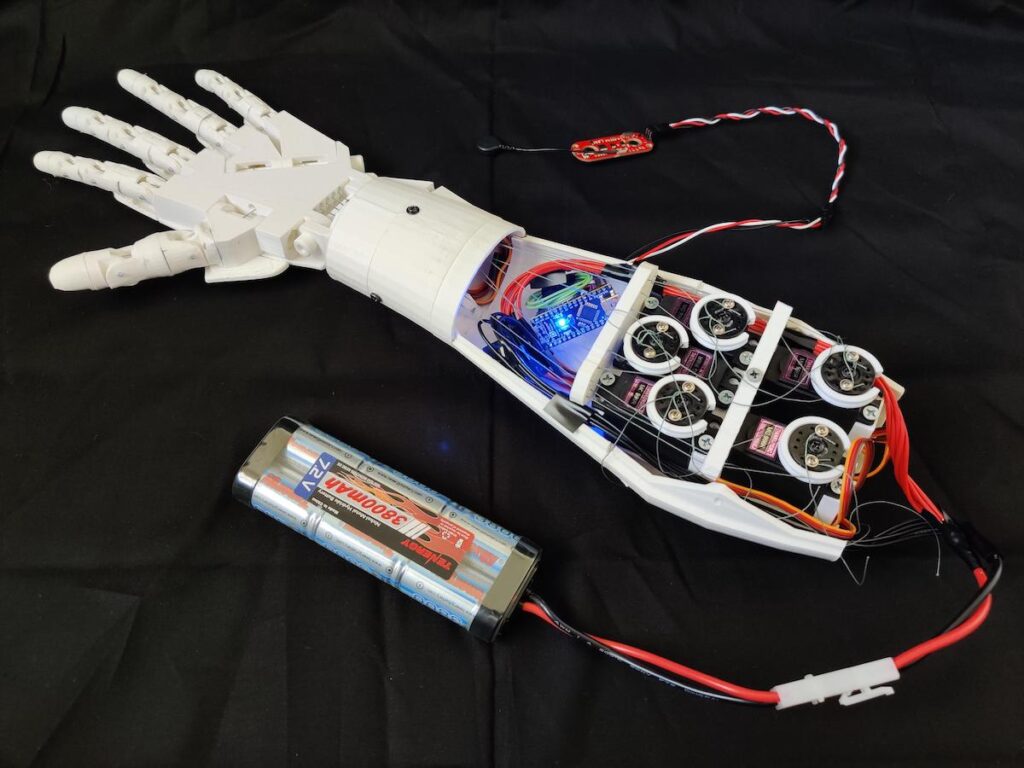

To begin this project, Ikram decided upon using the InMoov 3D-printed arm design from French sculptor Gael Langevin due to it being easy to construct. The hand itself contains a single wire connected to each finger, while the other end gets wrapped around a servo motor horn so that the finger can bend whenever the serv moves. A Myoware muscle sensor is responsible for reading the electrical signals generated by muscle contractions and converting them into a readable analog voltage, which is read by an Arduino Nano’s analog pin.

The program Ikram created for the Arduino simply takes continuous readings from the myoelectric sensor and checks if it above a certain threshold. Once it is, the servos are set to a position for contracting the finger, otherwise it releases tension from the wire and makes the fingers return to their original position.

To see more about this project, you can read Ikram’s post here on Instructables and watch its demo video below.

The post Designing a 3D-printed EMG bionic hand as a low-cost alternative to prosthetic limbs appeared first on Arduino Blog.