22

If you live somewhere prone to power outages, you might have thought about buying a generator. The problem is that small generators are cheap but — well — small. Big generators are expensive. [Jake von Slatt] had an idea. He has a “yard car” which we thought might be a junk car but, instead, it is an old car he uses to drive around his yard doing tasks. It has a winch and a welder. Now it has a big generator, too. You can follow the project in the three videos found below.

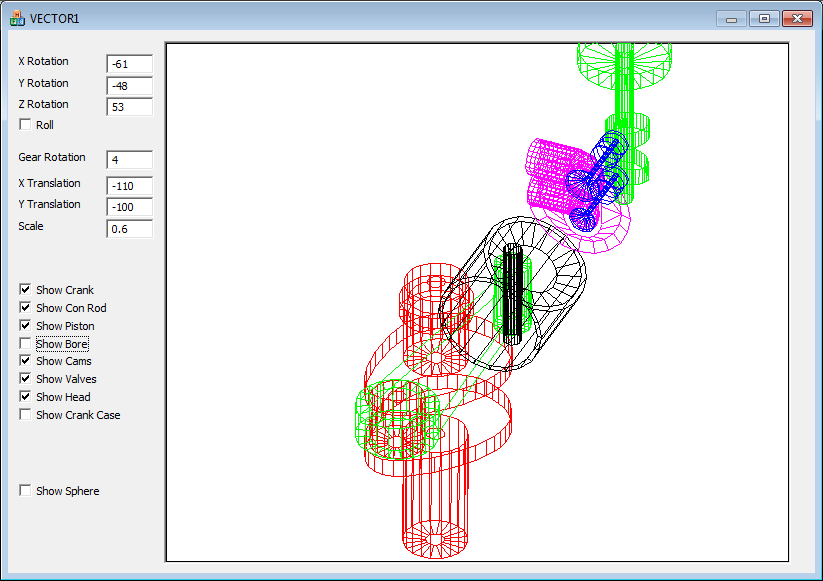

The project started with a scrap generator with a blown motor. Of course, the car has a motor so — in theory — pretty simple. Remove the generator from the motor and graft it to the car’s motor. But the details are what will kill you.

The first video shows the teardown of the generator unit and some planning. Some custom parts that were recovered from the scrap pile replaced some of the parts on the generator, including a custom casting leftover from another project that took a bit of machining to repurpose.

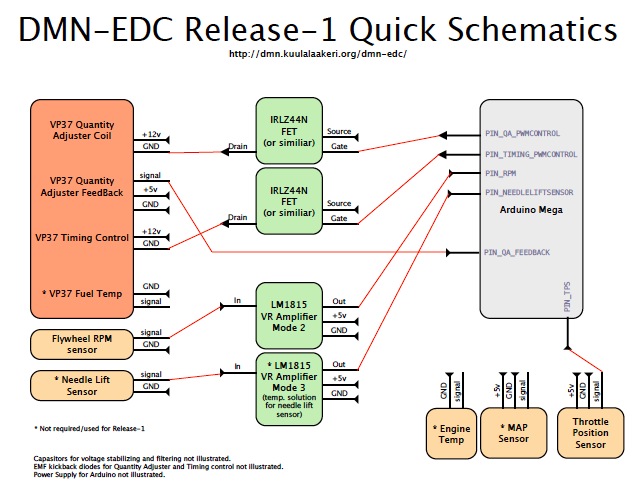

By the second video, he had a proof of concept working, but it had a small problem. He was controlling the speed of the motor with a stick on the accelerator linkage. So, he modified an idler from an AC compressor to limit the speed of the generator. The final video uses an Arduino to drive the cruise control to keep a steady RPM to the generator.

Overall, this is an interesting project both because it is unusual and useful, but also because of the wide range of skills [Jake] demonstrates — he knows his way around a machine shop, a car, and the Arduino. Pretty impressive!

We’d rather reuse a car engine than drive the generator ourselves. For some reason, that comes up repeatedly.