08

Almost all modern video games require either a gamepad or a keyboard and mouse, which means that they’re inaccessible to many people with disabilities that affect manual dexterity. Bob Hammell’s voice-enabled controller lets some of those people experience the joy of video games.

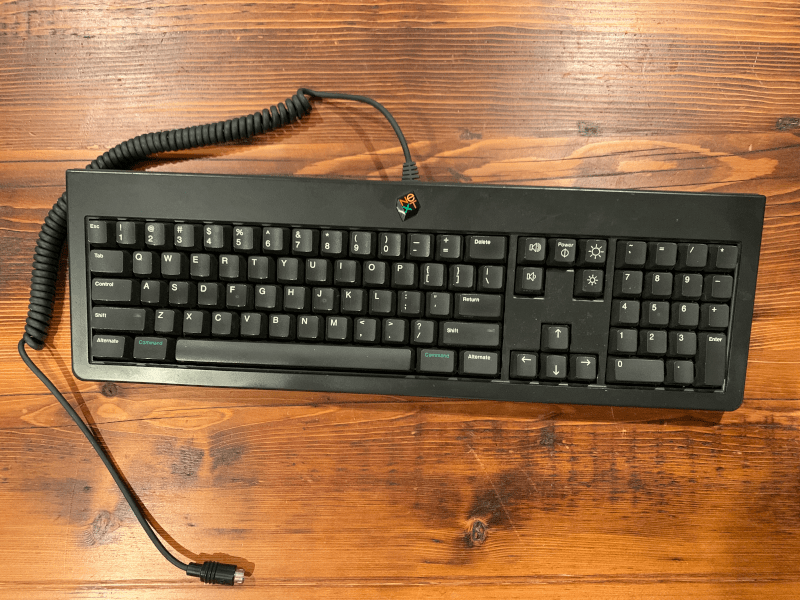

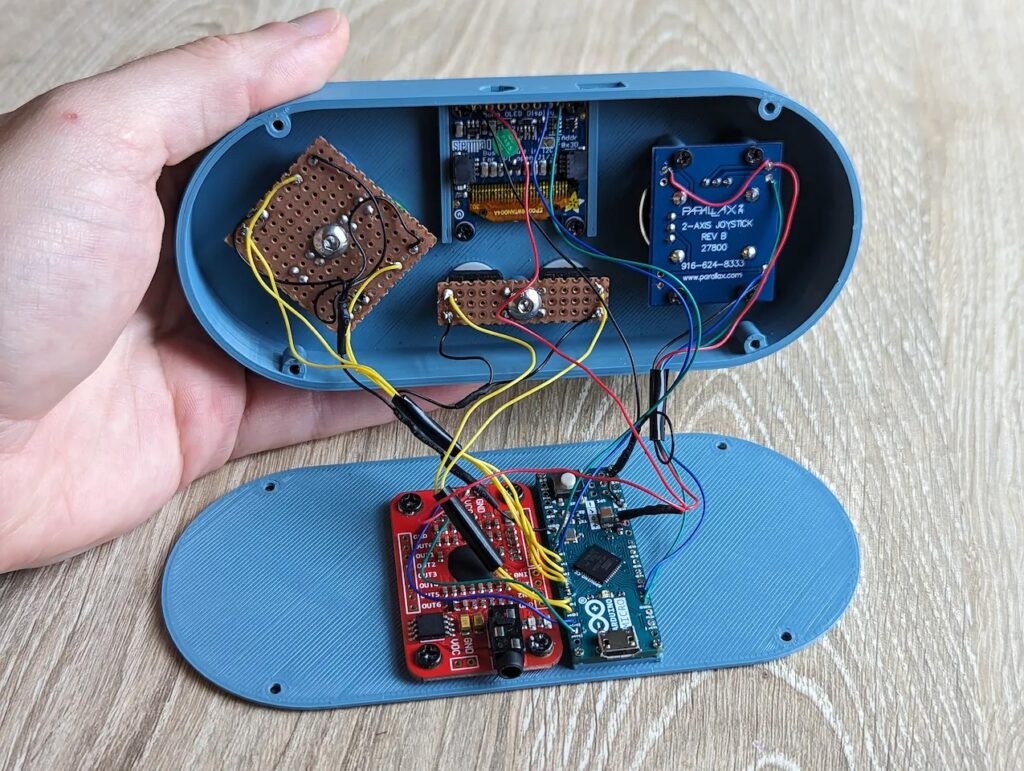

This is a simplified video game controller with a minimal number of physical buttons, but with special voice-activated virtual buttons to make up the difference. The gamepad only has six physical buttons, plus an analog joystick. That makes it much easier to handle than a typical modern controller, which might have a dozen buttons and two joysticks. If the player has the ability, they can utilize the physical controls and then speak commands to activate the game functions not covered by those buttons.

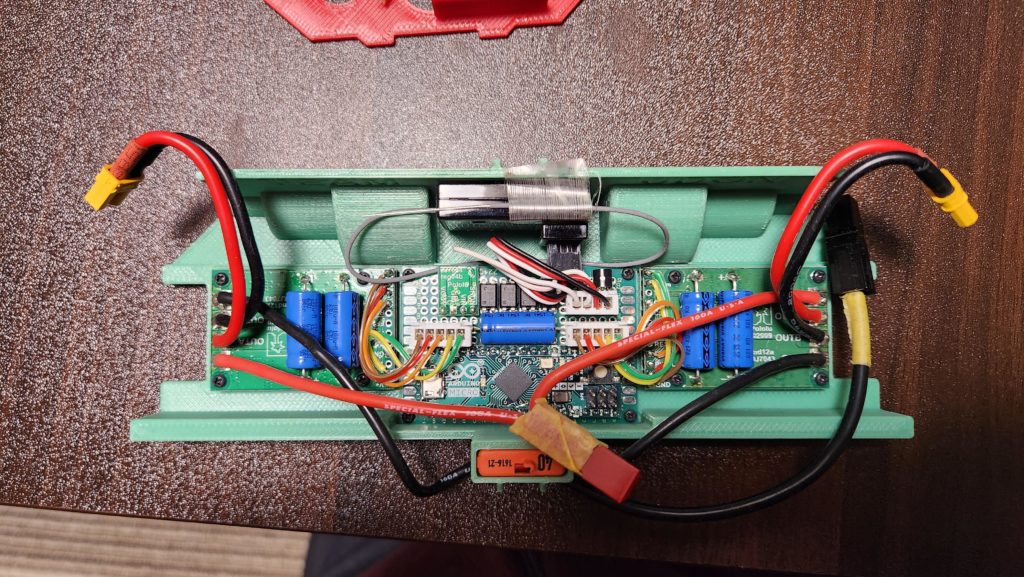

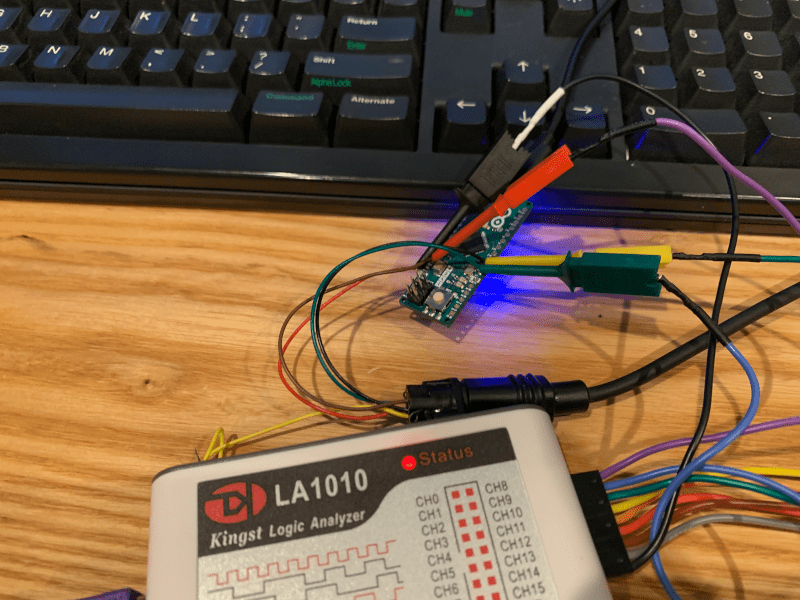

The controller’s brain is an Arduino Micro board, which Hammell selected because it can be configured to show up as a standard USB HID gamepad or keyboard when connected to a PC. The physical controls are an Adafruit analog two-axis joystick and tactile switches. An Adafruit 1.3″ OLED screen displays information, including the status of the voice activation.

An Elechouse V3 Voice Recognition Module performs the voice recognition and it can understand up to 80 different commands. When it recognizes a command, like “menu,” it tells the Arduino to send the corresponding virtual button press to the connected computer. It takes time for a person to speak a command, so those are best suited to functions that players don’t use very often.

If you know someone that would benefit from a controller like this, Hammell posted a full tutorial and all of the necessary files to Hackster.io so you can build your own.

The post Voice-enabled controller makes video games more accessible appeared first on Arduino Blog.