Hello readers

Today we continue with the series of articles on basic electronics with this introductory article about the capacitor.

What is a capacitor? A very simple answer to that question is a part that stores electric current for use in the future. How is this so? A capacitor is made up of two conductive plates, separated by a dielectric. The plates can be made from conductive material such as aluminium, and the dielectric is between these conductive plates. Dielectrics can be made from nothing (i.e. be a tiny gap between the plates or a vacuum), paper, plastic film, glass, a special kind of fluid, or ceramic material.

When a difference in potential exists across the plates (a change in voltage) an electric field is created between the plates, which stores electrical energy – charging the capacitor. When the potential difference is removed, the energy will leak through the dielectric until the potential no longer exists – in other words discharging the capacitor. The amount of energy that a capacitor can hold – its capacitance, is a unit of measure called the Farad.

The term farad is named after an Englishman by the name of Michael Faraday, a genius chemist and physicist that discovered (amongst many other things) the concept of electromagnetic fields. Anyhow, one farad (F) is quite a lot of energy, so capacitors usually store much less. The most common units of measurement are the following:

- picofarads – pF – 10^-12 – 0.000 000 000 001 F

- nanofarads – nF – 10^-9 – 0.000 000 001 F

- microfarads – uF – 10^-6 – 0.000 001 F

As well as the capacitance value, the other common parameters of a capacitor are:

- the voltage (never exceed your voltage!)

- leakage current – capacitors are not perfect and do leak a very tiny amount of current, usually in the micro-ampere range

- tolerance – similar to resistors, actual versus manufactured values can vary – sometimes up to 20% either way

- working temperature – always check this if your project involves extreme temperatures

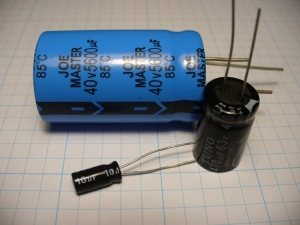

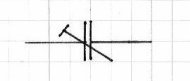

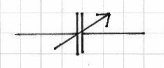

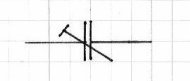

It is always interesting to read component data sheets, and this is no exception for capacitors. You can learn a lot about the individual parameters and design your project accordingly. Here is a typical example of a data sheet for an electrolytic capacitor from Vishay. And here are the schematic symbols for non-polarised and then polarised capacitors:

At this point let’s have a look at the various types of popular capacitors:

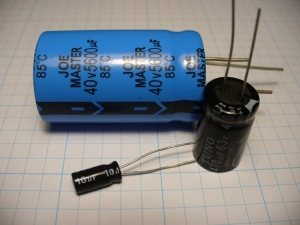

Electrolytic Capacitors

These are used when very high values of capacitance are required, for power smoothing, spike suppression and so on. They consist of two sheets of aluminium foil, one sheet covered with an oxide coating, separated by paper soaked in electrolye – this is rolled up and inserted into a cylinder, with two wires inserted. As the electrolyte is a liquid, it is affected by ambient temperature. Therefore as temperature increases, the capacitance increases – and vice versa. Therefore temperature extremes need to be taken into account, and perhaps other types of capacitors used. The capacitors in the photo above are radial capacitors; you can also find axial capacitors with one lead at each end. Note that electrolytics are polarised! They have a positive and negative lead – the negative is normally indicated by the striped-arrow line (see above).

V-chip capacitors

These are surface-mount electrolytic capacitors, for example these two on my Arduino Duemilanove (below).

Ceramic capacitors

These are very small, constructed from layers of aluminium and ceramic material.

Their capacitance is also very low, the lowest I have seen is 0.015 picofarads. Typically used in situations that have high frequencies, such as spike protection for integrated circuits. Reading the value is quite simple, the first two digits are the significant figures, and the third is the multiplier. The result is always picofarads. For example. 121 is 120 picofarads, 8.2 is 8.2 picofarads, 12 is 12 picofarads. If there is a letter suffix, this indicates the tolerance:

- C = +/1 0.25pF

- D = +/- 0.5 pF

- J = 5%

- K = 10%

- M = 20%

- P = +100%/-0%

- Y = -20%/+50%

- Z = -20%/+80%

If there are numbers after the tolerance, they normally state the maximum working voltage. If your capacitor does not have a tolerance printed on it, assume it is between 10 and 20%. Or better yet, replace it with a better capacitor that states the tolerance.

Polyester capacitors

These are also very popular for high-frequency circuits, as they can discharge very quickly and have a very low leakage. The older styles (green/brown above) – read their values is the same as the ceramic capacitors (above), with a slight difference – sometimes (!) the voltage rating is before/above/below the value code. So using the green example above which reads “2A683J”, this breaks down to the voltage rating 2A, and the value 683, then the tolerance J. Voltage ratings are:

- 2A – 100V DC

- 2E – 250V DC

- 2G – 400 V DC

- 2J = 630V DC

So the 2A683J will have a voltage rating of 100V, a tolerance of 5%, and a capacitance of 68000 picofarads (0.068 uF or 68 nF).

Please note – this coding does seem to vary by manufacturer. Some will actually have (e.g.) 630V printed on them, and some even have their own coding. If you are unsure of the voltage rating, one has to really examine the circuit the capacitor is located in, or hunt down the data sheet. When buying new parts, it pays to get the data sheet from the distributor, then file it away indexed with your stock control database.

The newer styles (blue above) are different again. This one is 0.47 uF 63 volts 10% tolerance.

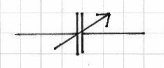

Variable capacitors

There are two main types – trimmer capacitors (above right) used for fine-tuning; and normal variable (or mini-tuning) capacitors (above left) used for applications such as radio tuning. Usually have a set range, for example the tuning capacitor’s range is 60 to 160 picofarads. The schematic symbol for trimmer capacitors is:

and for variable capacitors is:

Tantalum capacitors

Can be used as a replacement for electrolytic capacitors where space is at a premium, and a more accurate and less leaky (electrically that is) solution is required. Tantalums are also polarised (see the tiny ‘+’ in the photo above).

Surface-mount capacitors

There are many types of capacitor in surface-mount packaging. Hover over the images below for descriptions:

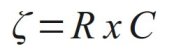

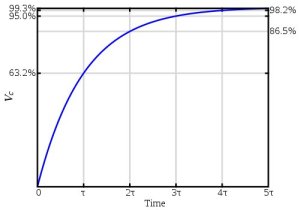

Mathematics of capacitors

Working with capacitors is easy, however some mathematics may be required. If you recall the formulae associated with resistors, you will find this quite easy.

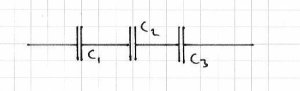

Capacitors in parallel

This is simple – the total capacitance of parallel capacitors is the sum of the lot. However – the voltage parameter of the group is the minimum value used. Furthermore, do not mix capacitor types.

For example – C1 is 10 uF, 63V; C2 is 470 uF 25V; C3 is 1000 uF 16V. With these three in parallel, the capacitance is 1480 uF; and the maximum voltage is 16 volts.

{Thank you readers for checking my maths! – John  }

}

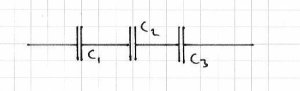

Capacitors in series

This is somewhat complex, but can be done!

Again, always use the same type of capacitor, and the lowest voltage rating applies to the entire group.

Again, always use the same type of capacitor, and the lowest voltage rating applies to the entire group.

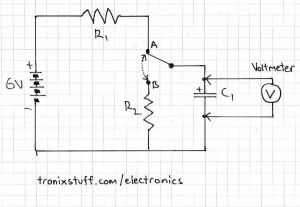

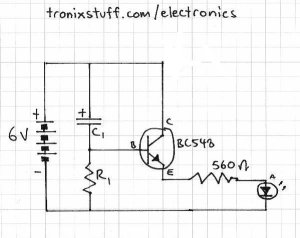

Smoothing DC current with a capacitor

When AC current is converted to DC current using a bridge rectifier (four diodes) the resulting DC current is not very smooth… that is the actual voltage changes between zero and the maximum over very short periods of time. A capacitor can be placed between the positive and negative rails immediately after the bridge rectifier to solve this problem. It does this by charging to capacity when the DC current is above zero, then when the voltage from the rectifier drops the capacitor supplies current, acting as a reservoir. This in turn maintains the supply voltage.

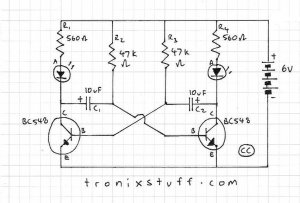

Using the circuit above, we will demonstrate the smoothing process in the video clip below. The first part shows the AC current on the oscilloscope; the second part shows the noisy DC current at the points 4 and 8 on the circuit above. Then a 470 uF electrolytic capacitor is inserted across points 4 and 8 – you can see the difference and how smooth the current has become. There is still a slight ripple, but I cannot show this due to the low resolution of my oscilloscope. When building a power supply, one would place the linear regulator after the capacitor in our example.

For the record I am working on finding a better oscilloscope… slowly!

Well that wraps up my introduction to capacitors. In the next fortnight we will look at another aspect of using capacitors in DC circuits, so stay tuned.

As always, thank you for reading and I look forward to your comments and so on. Furthermore, don’t be shy in pointing out errors or places that could use improvement. Please subscribe using one of the methods at the top-right of this web page to receive updates on new posts. Or join our new Google Group.

Otherwise, have fun and make something!

Some information for this post is from: historical info from Wikipedia; various technical information and inspiration from books by Forrest Mims III; tantalum and SMD capacitor photos from Farnell Australia.