05

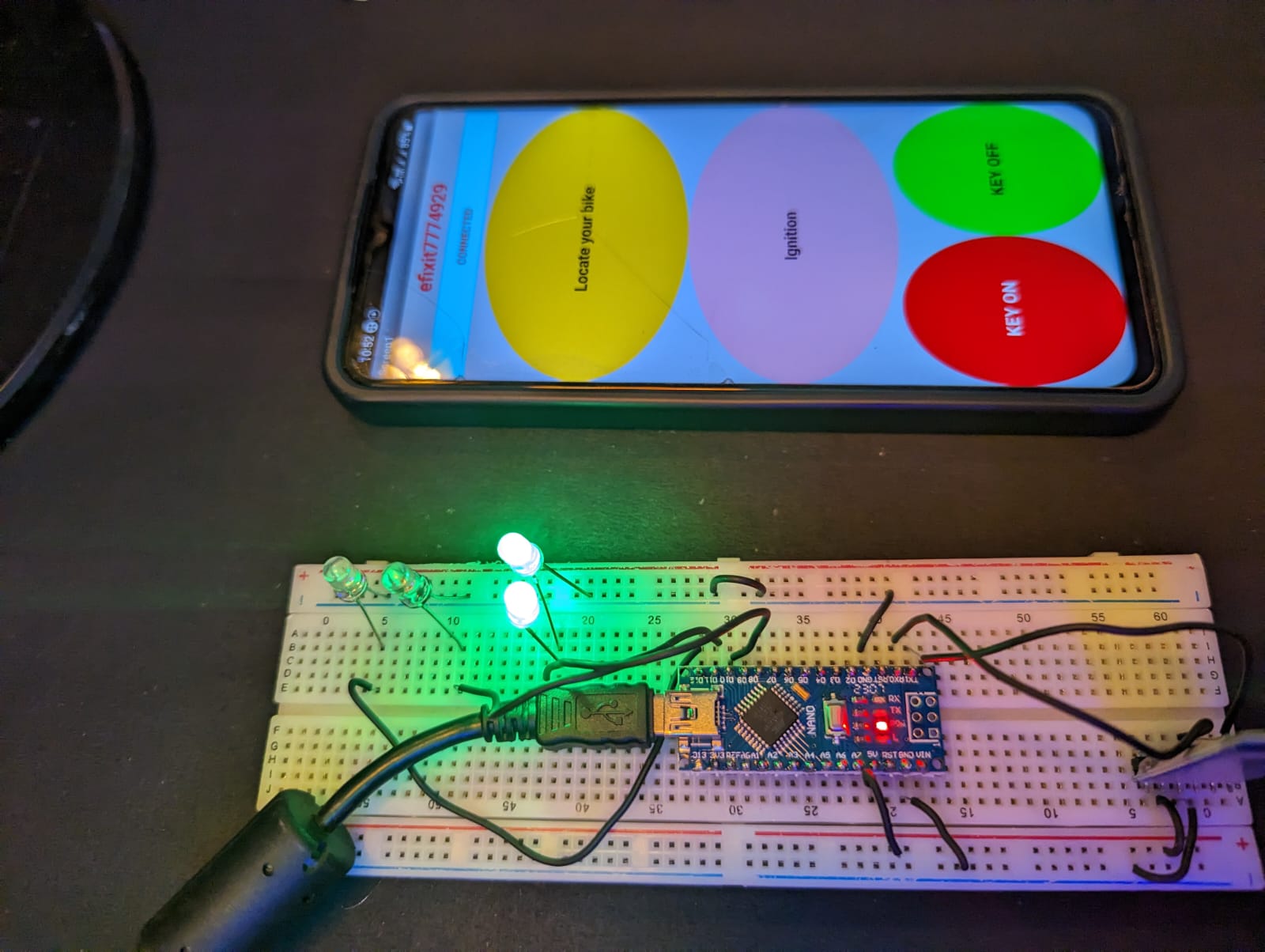

Wanna start your bike without a key? Yes, we have made a project for all tech enthusiasts who wanna integrate the technology into their bikes. with the help of keyless bike project, you can control your bike fully like starting the engine and ignition of the bike. and you can locate your bike by clicking on the locate bike key. i think this is a very interesting project. Also, I will attach this product in my bike too soon and the video will be uploaded on my youtube and Instagram.

Introductions

This keyless bike Arduino project is very easy to use. There is one application for Android mobile phone. through this application you can control your bike properly.

- you can turn on and off your bike

- you can on self start the bike

- you can locate your bike by horn and indicator control

these things you can control by our project. we will use wireless communication to connect the bike with the mobile phone.

To make this project we are going to share all the detail here. if you really want to learn and make this project follow all the steps. you need to learn some basics of electronics which are already given on our website. So, let get started with any delay.

First we need to make a list of required components.

Required components

- Arduino nano

- Bluetooth HC-05

- LEDs

- 4 channel relay

- Usb A type cable

- Breadboard

- Hook up wires

As you can read in the required components you need only a few components to make this keyless bike project. Now, let’s try to understand what is the purposes of the given components.

Arduino nano is controller and uses as a main part of this task. Arduino nano have the capability to store the data, compare the data, operate sensors , modules and much more. so , arduino nano is controlling the Bluetooth module here. and relays. it getting the data on the Bluetooth module and compare this data with the programmed data and turn on and off relays.

Relays are the electronic switches. which can turn on and off any circuit by a small amount of current such as we need to press any key to turn of the light or fan same as the relay can turn off and on by applying a small voltage. so here we turn off and on the bikes things like ignition, engine, and indicator.

Bluetooth module is the wireless communication in this keyless bike project. which make the connection between bike and the mobile phone. we already make an android app which will connect the bike through the Bluetooth hc-o5 module. the app link is given below.

Download Android app.

Circuit diagram

Code

void setup()

{

Serial.begin(9600); // buart rate

pinMode(12,OUTPUT); //

pinMode(9,OUTPUT);

pinMode(10,OUTPUT);

pinMode(11,OUTPUT); // LED

//digitalWrite(12,HIGH); // relay module high

}

void loop()

{

if(Serial.available()>0)

{

char data= Serial.read();

Serial.println(data);

if(data=='A')

{

digitalWrite(10,HIGH);

delay(300);

digitalWrite(10,LOW);

delay(300);

digitalWrite(10,HIGH);

delay(300);

digitalWrite(10,LOW);

delay(300);

digitalWrite(10,HIGH);

delay(300);

digitalWrite(10,LOW);

delay(300);

digitalWrite(10,HIGH);

delay(300);

digitalWrite(10,LOW);

delay(300);

}

else if(data=='C')

{

digitalWrite(11,LOW); // LED OFF

delay(500);

}

else if(data=='D')

{

digitalWrite(11, HIGH); // LED OFF

delay(500);

}

else if(data=='B')

{

digitalWrite(12,LOW); // LED OFF

delay(1000);

digitalWrite(12,HIGH); // LED OFF

delay(1000);

}

else

{ }

}

}Upload the given code in your Arduino by connecting the cable. if you have any trouble uploading the sketch you can get help from our website.

How to operate the application.

step.1

- give power to the system

- Go to the phone setting

- select the Bluetooth setting

- click on the pair new device tab

- Select the HC-05 device there

- now open the given application

- click on the connect tab in application

- select the HC-05 device

PCBWay PCB Prototyping Services

I have assembled the whole circuit on a breadboard. As you know breadboard assembly is not effective for this type of project. So, PCBWay offers Rapid PCB Prototyping for Your Research Work. I personally, recommend PCBWay because you can get your first-try boards right in 24 hours!

The prototyping stage is the most critical period of time for engineers, students, and hobbyists. PCBWay not only makes your boards quick but also makes your job right as well as cost-effective. This greatly reduces your cost and shortens the time for developing your electronic

PCBWay can provide 2 Layer PCBs to highly advanced HDI and flex boards. Even though the PCBs they produce differ a lot regarding functionality and areas of use. I am impressed with the quality of the boards, the delivery time, and the cost-effectiveness

Keyless bike project Working

When application is connected to the device the connect tab will convert top the connected in the application. and when any key is press the phone will sends a character to the Bluetooth module which is attached to thee arduino and system.

For example if you press turn on bike tab in application the phone will sends ‘A’ to the Arduino and system and now Arduino will compare this data to the programmed we have written. if anything found to the similar to this data it will be start that condition.

like if (receive_data==’A’)

then, bike start.

if the condition is not true then bike will not start.

same in this way the whole system will work.

Thanks for reading, if you have any doubt you can ask us in comment section.

The post Keyless bike Project using Arduino and Android app appeared first on Techatronic.