27

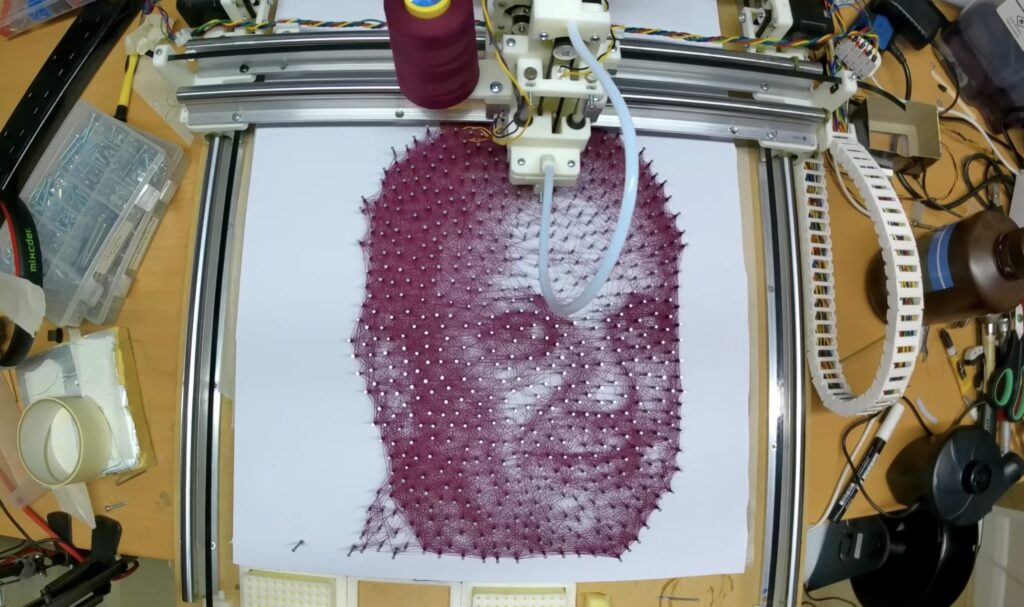

String art is impressive precisely because it is so difficult to make. Even a simple piece of string art will contain hundreds of feet of thread carefully looped around posts to create areas of varying density that act as shading. Everything from calculating the string’s path to physically laying down the string is a challenge. But after an immense amount of work, Paul MH was able to develop a machine that can produce string art at the touch of a button.

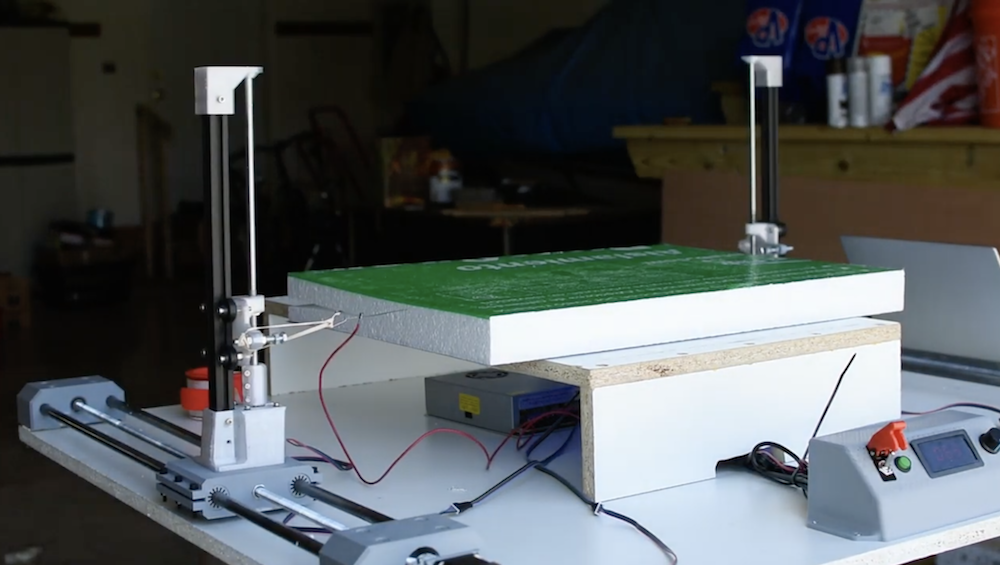

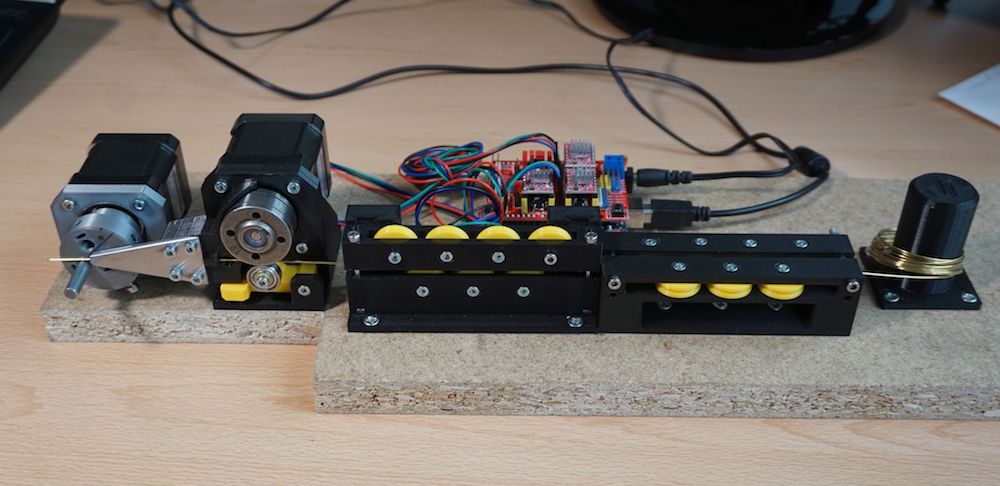

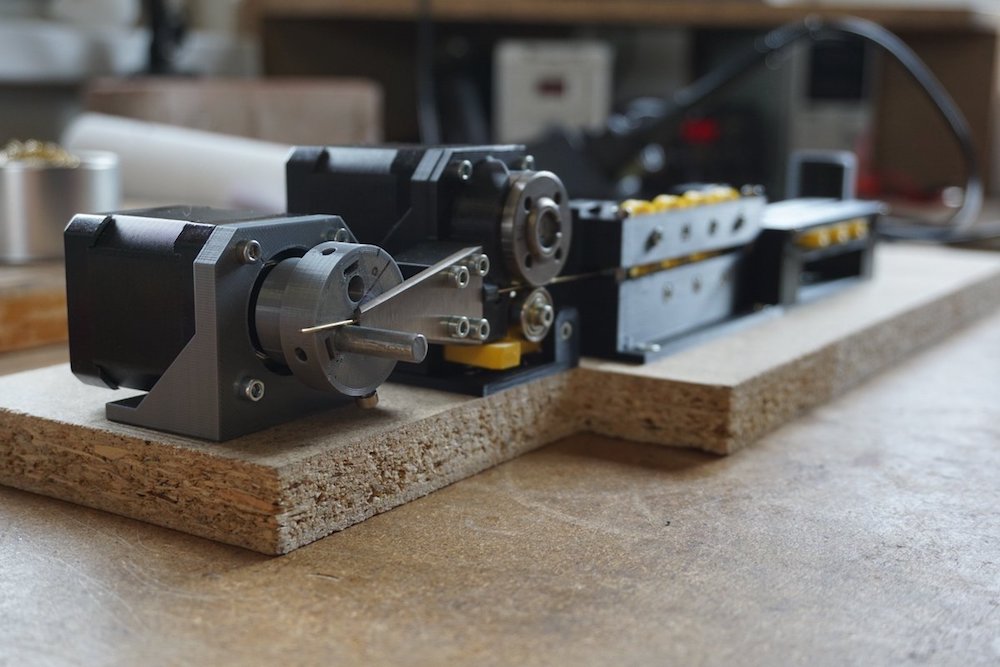

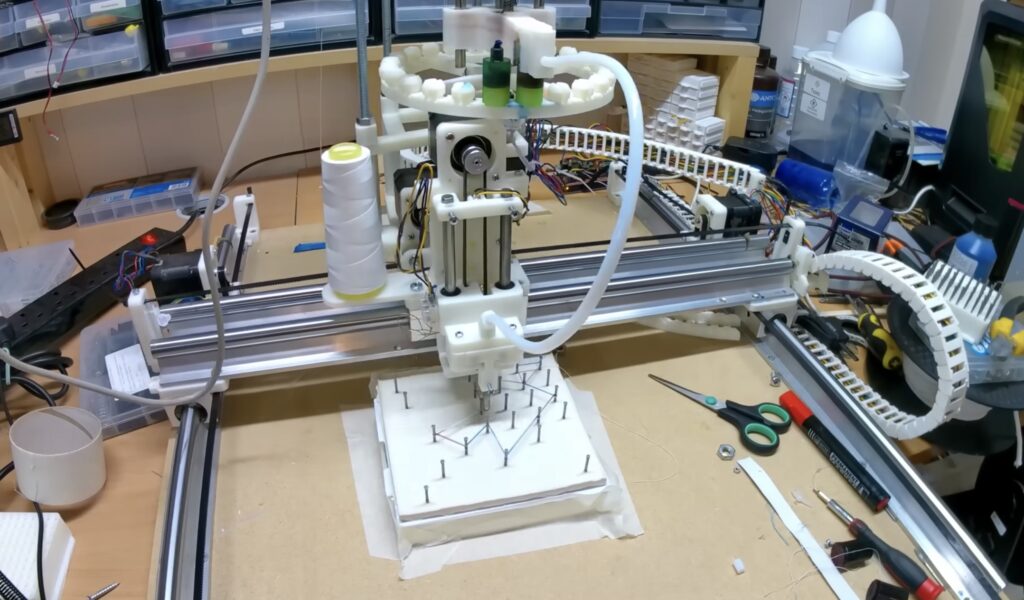

Paul spent years working on this project and it shows. Every step of the process required trial-and-error with different prototypes. To create an art piece, the machine first has to insert dozens or hundreds of nails into the foam bed. That necessitated the invention of a mechanism to feed nails and a neural network to verify that each nail feeds properly. The machine then has to convert an image into a string path, with that path avoiding collisions with nails, looping around nails enough to maintain tension, generating the proper string density, and preventing any tangles.

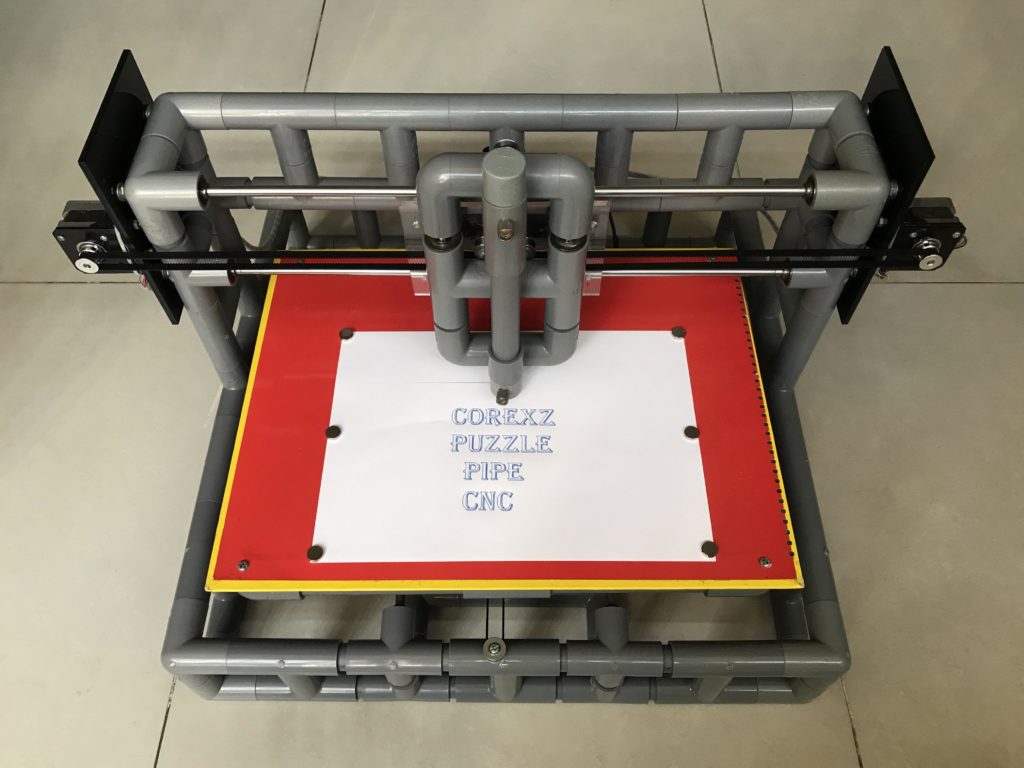

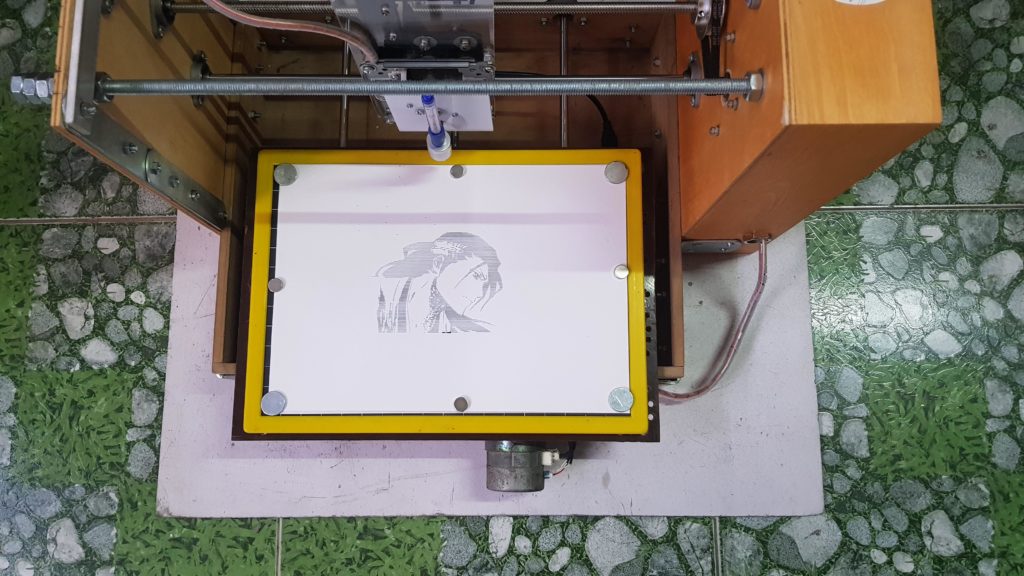

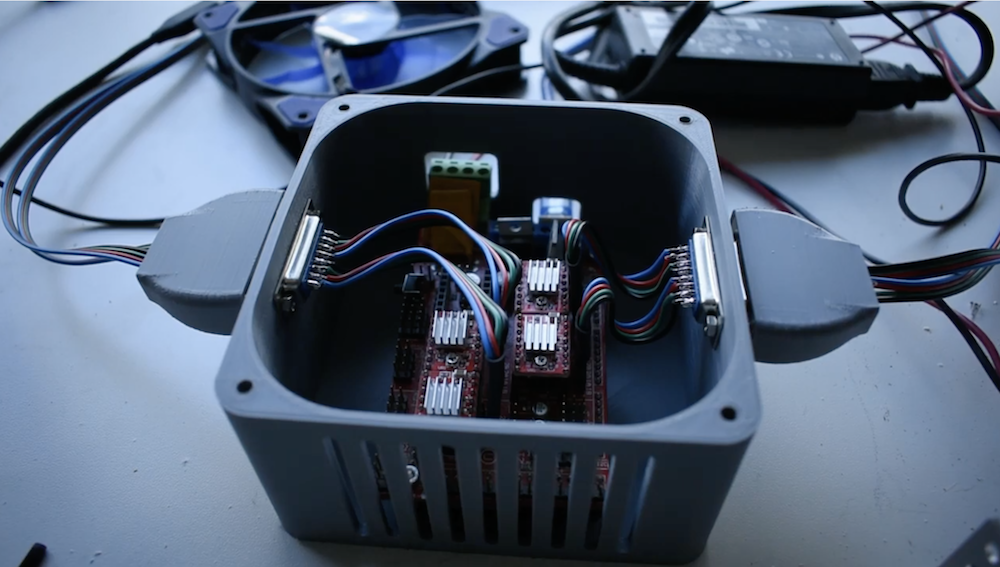

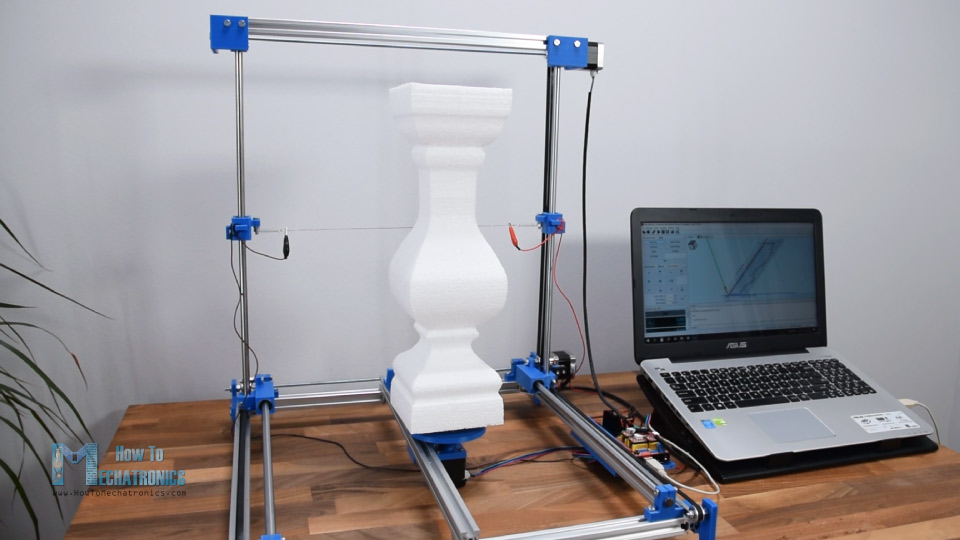

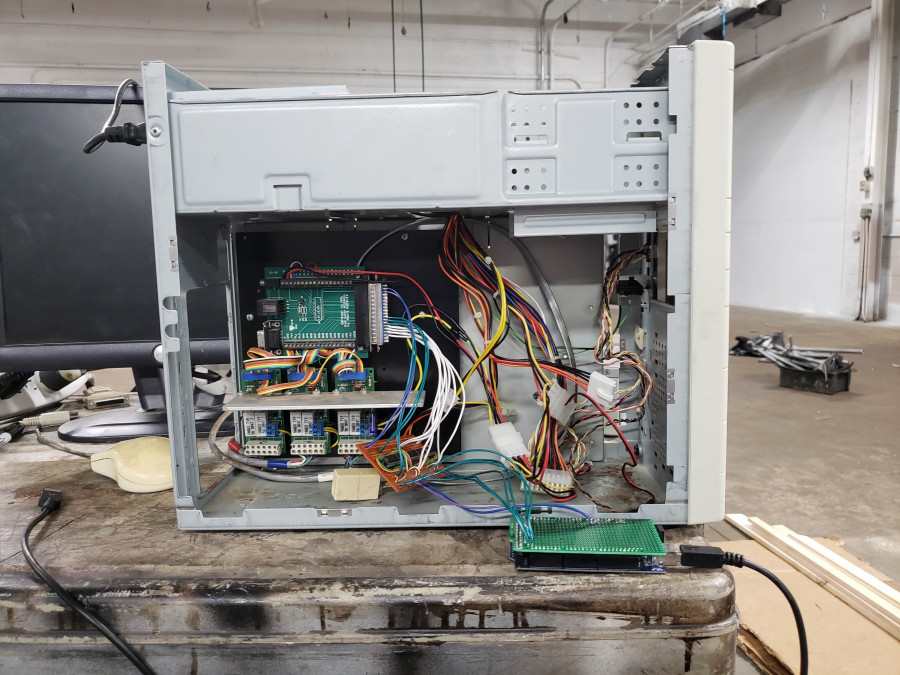

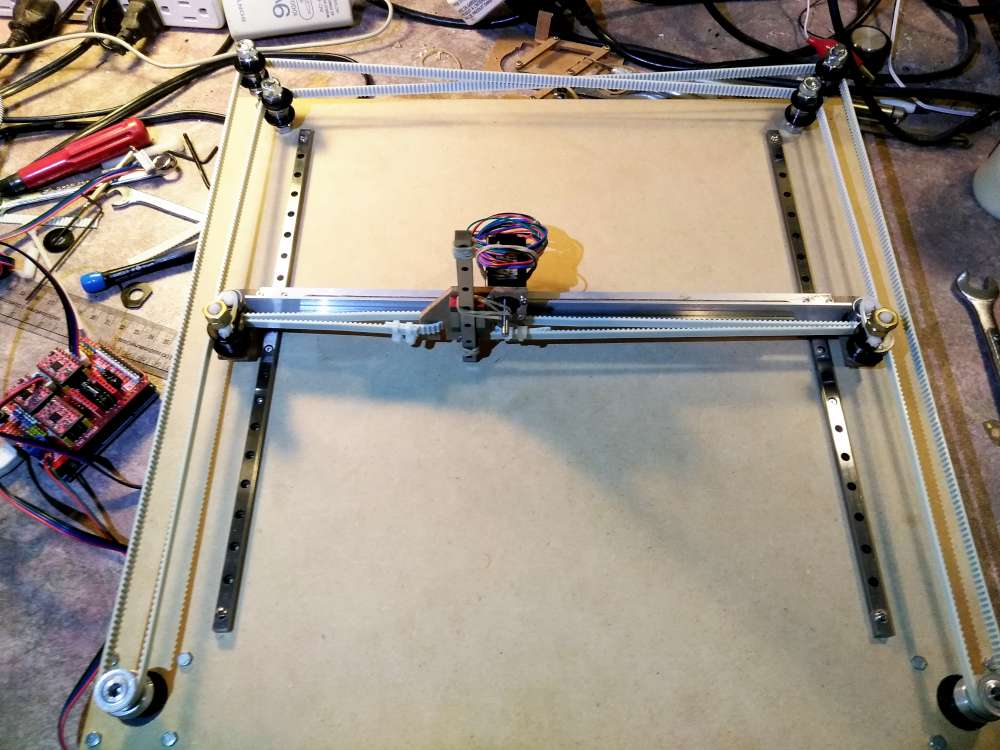

At its heart, this is a CNC machine that accepts custom g-code generated by Paul’s software. That G-code runs on an Arduino Mega 2560 board, which controls the machine’s motors through a RAMPS 1.4 shield. The concept is similar to a conventional DIY CNC router and the kinematic system is familiar, but this machine needed a multitude of custom parts. Most of those were 3D-printed over many iterations until Paul had a working machine.

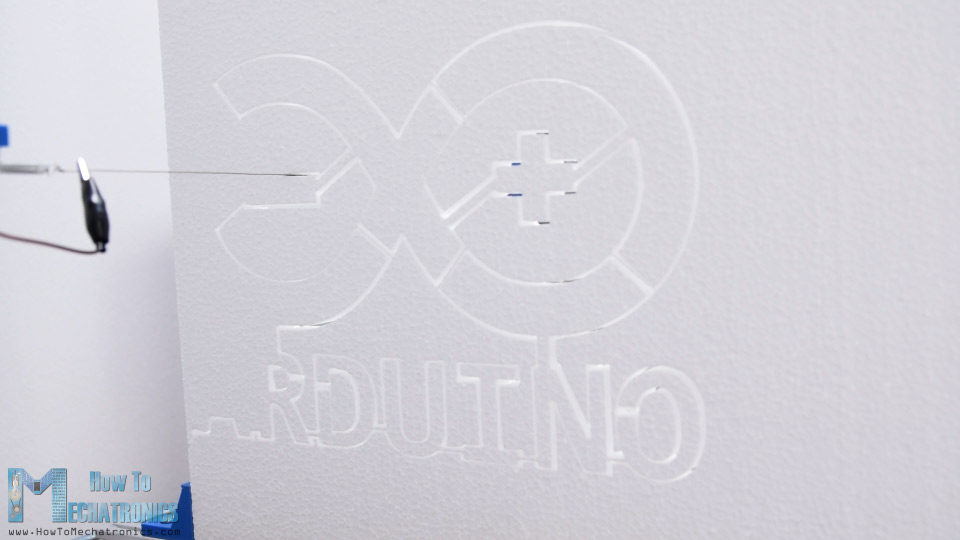

As you can see in Paul’s recent video update, the machine can produce very nice string art. It can take any image as input, but high-contrast pictures without a lot of fine detail work the best.

The post This machine automatically threads beautiful string art appeared first on Arduino Blog.