14

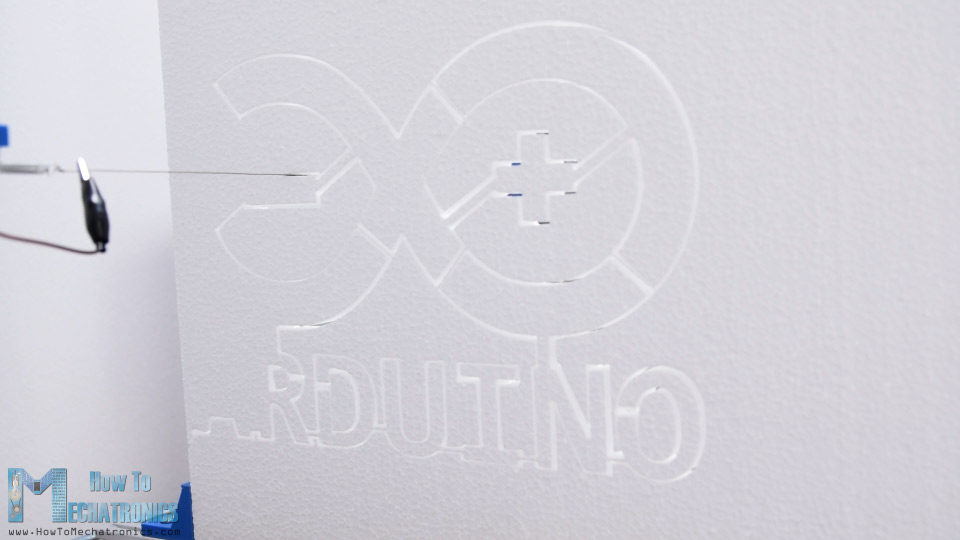

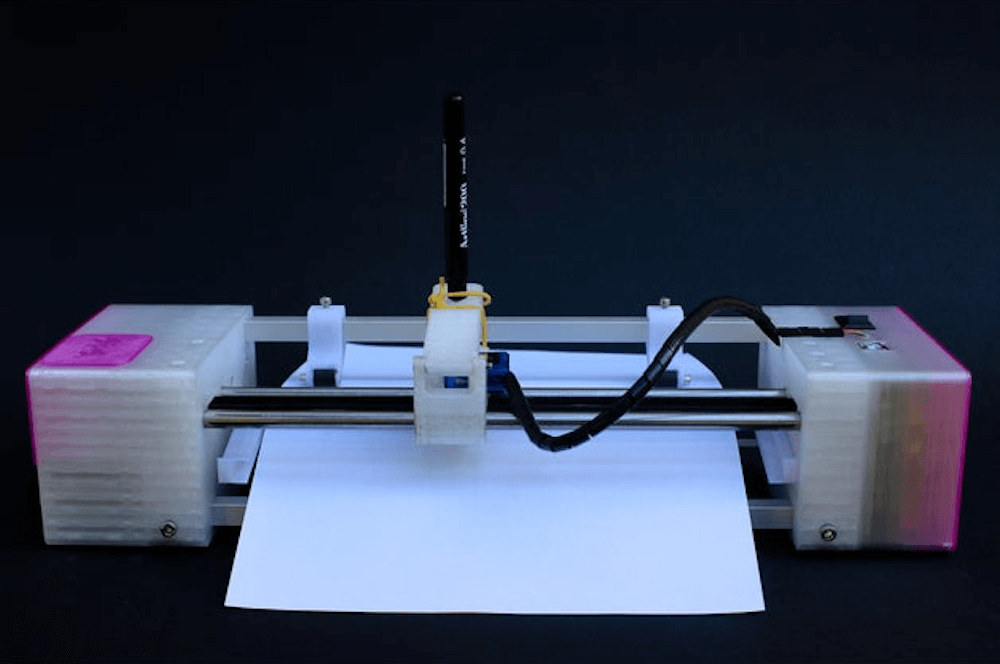

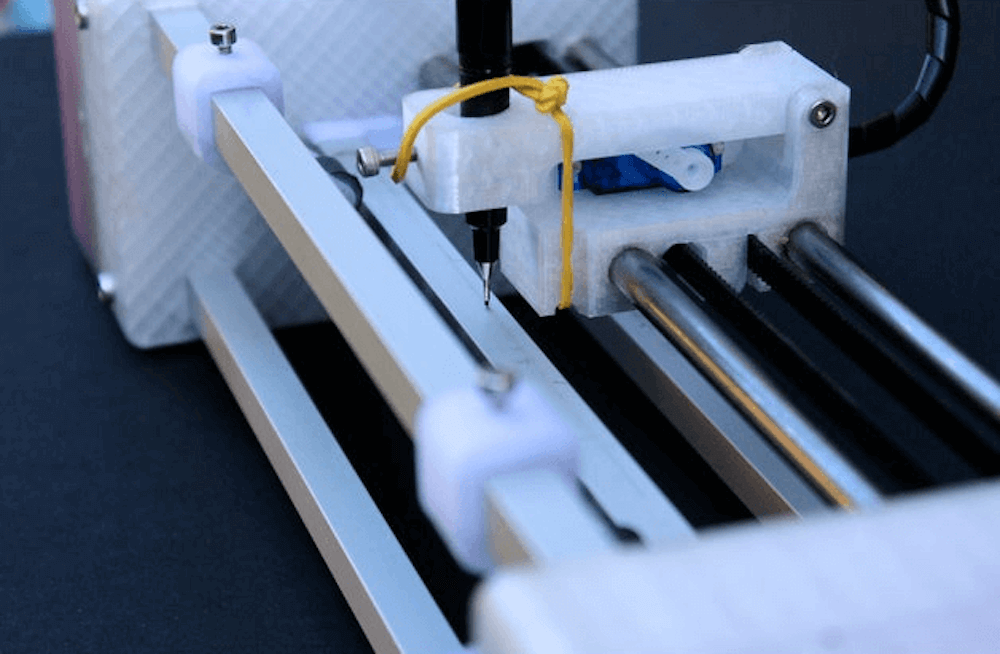

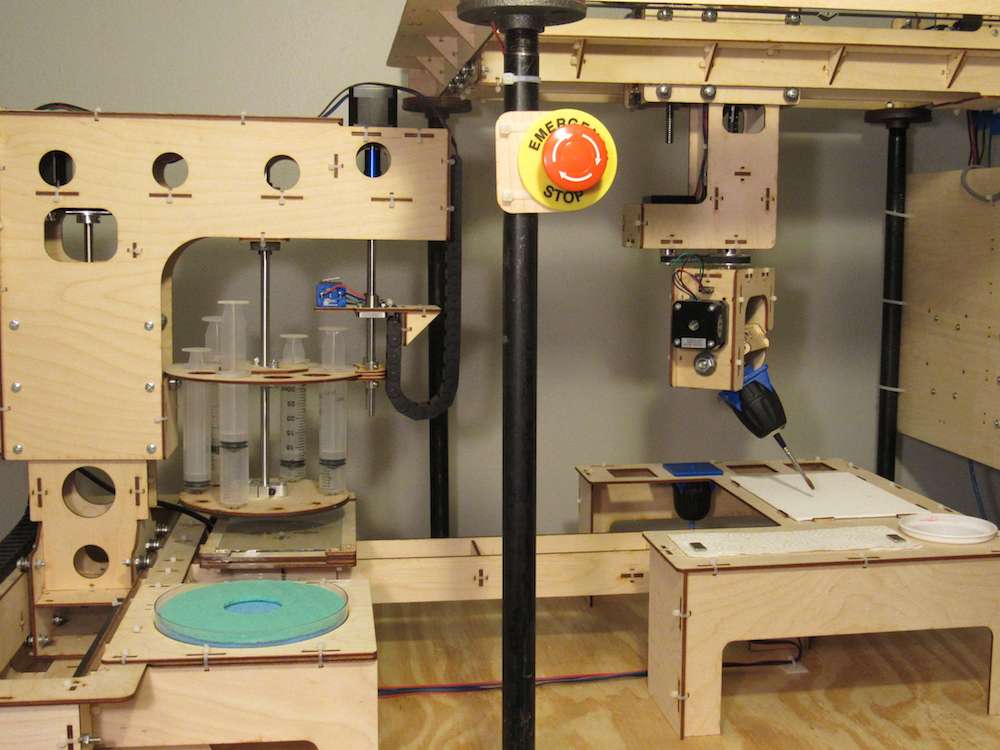

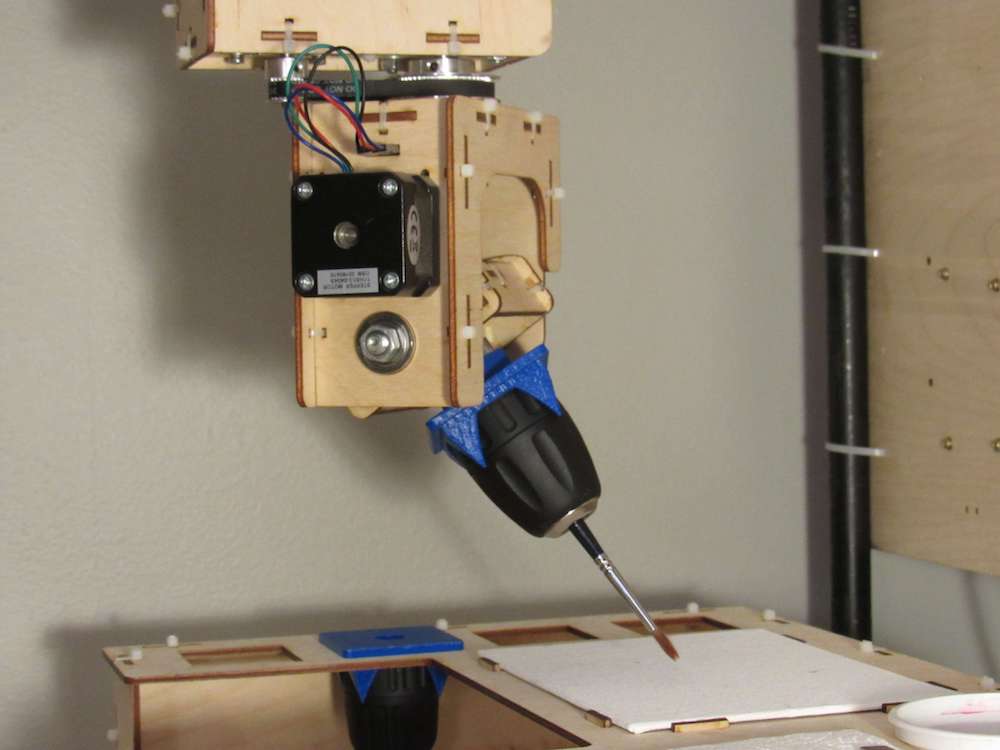

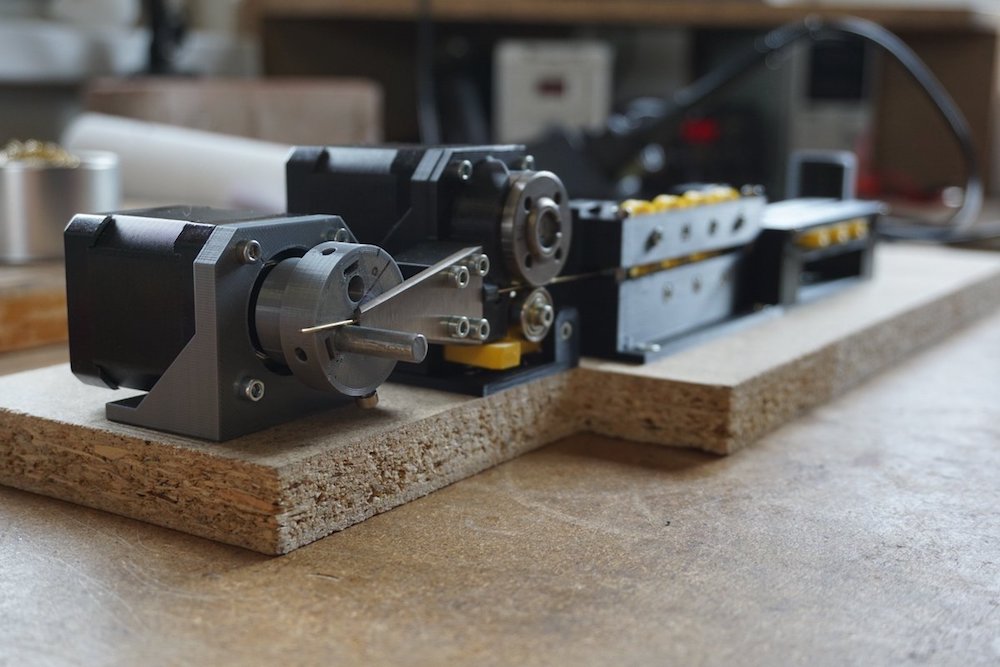

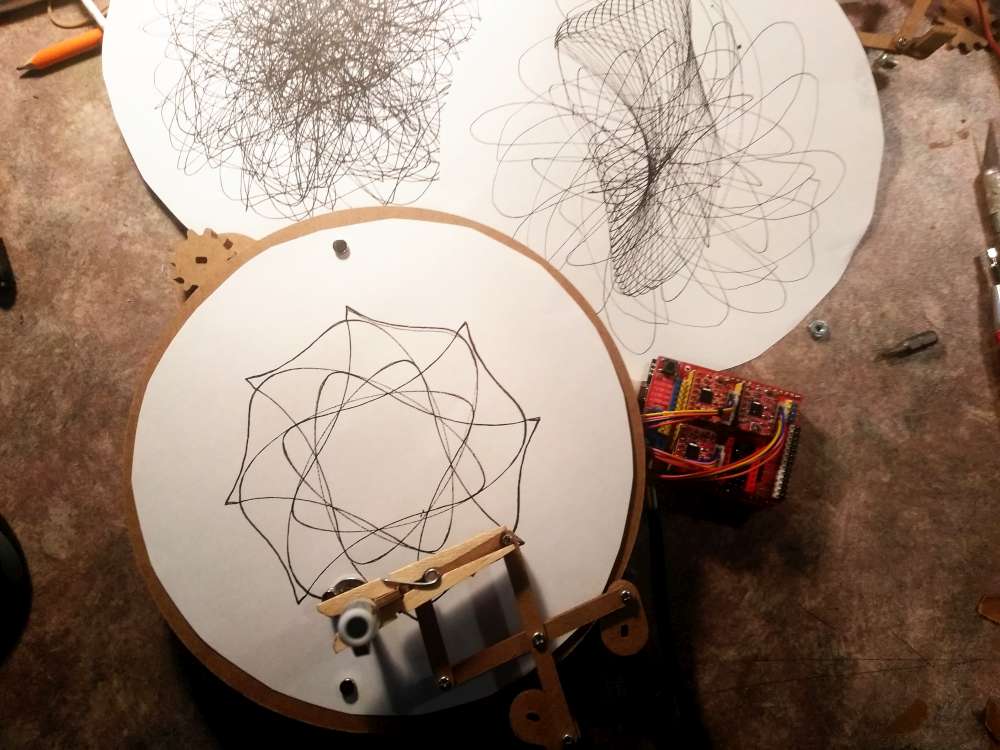

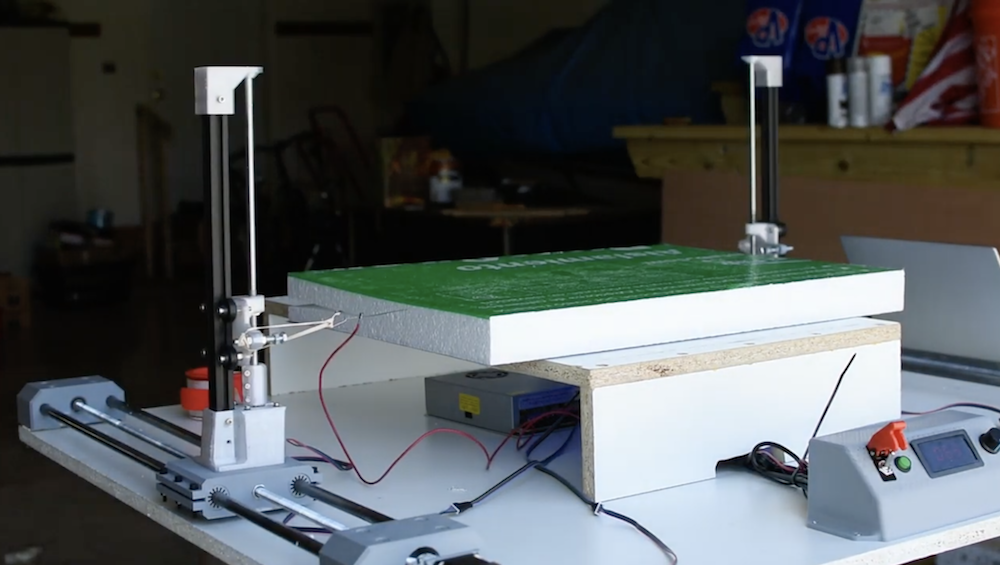

When working with Styrofoam, a conventional CNC machine like a router or laser cutter just won’t do. However, as shown in Michael Rechtin’s excellent video below, a hot wire can carve foam like butter, creating custom wings for RC aircraft or whatever else you can dream up.

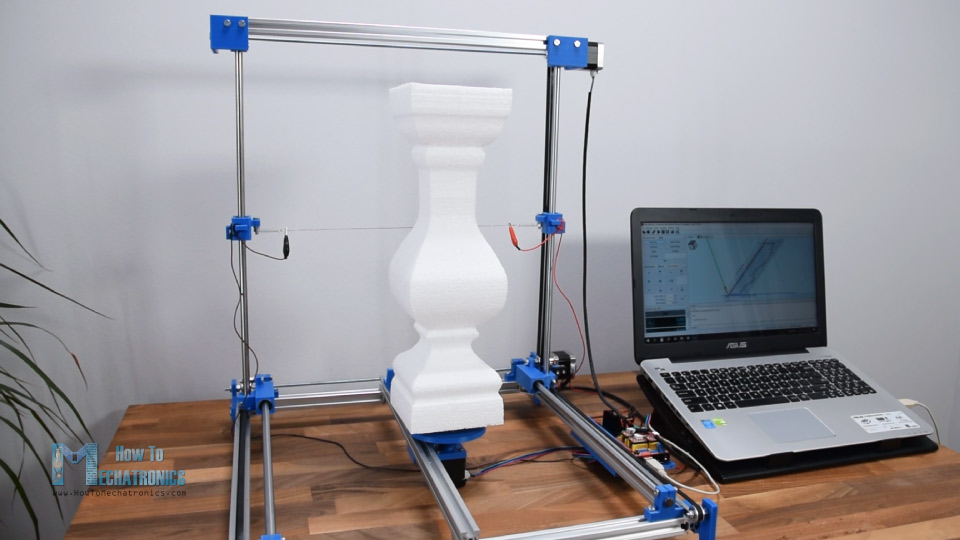

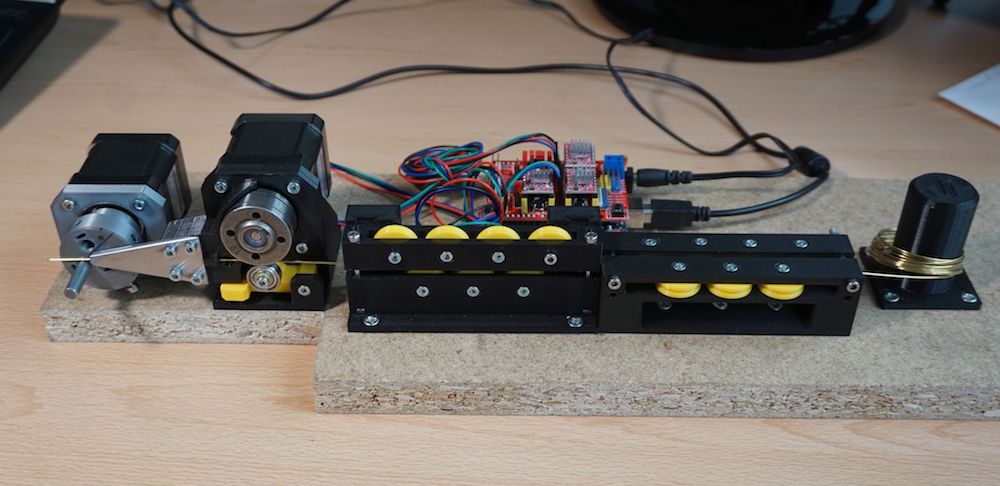

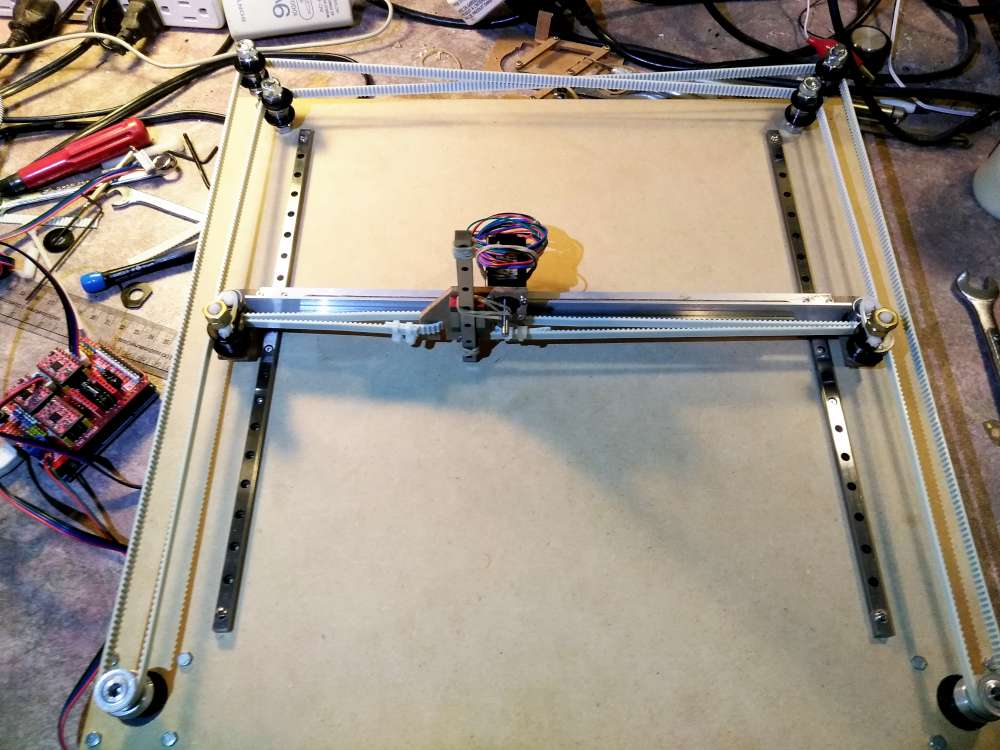

Rechtin’s build uses a double gantry system to pull the wire in a horizontal and vertical directions. As each is mechanically independent of the other, they can move in tandem, or in a skewed orientation for cutting across both the horizontal and vertical planes.

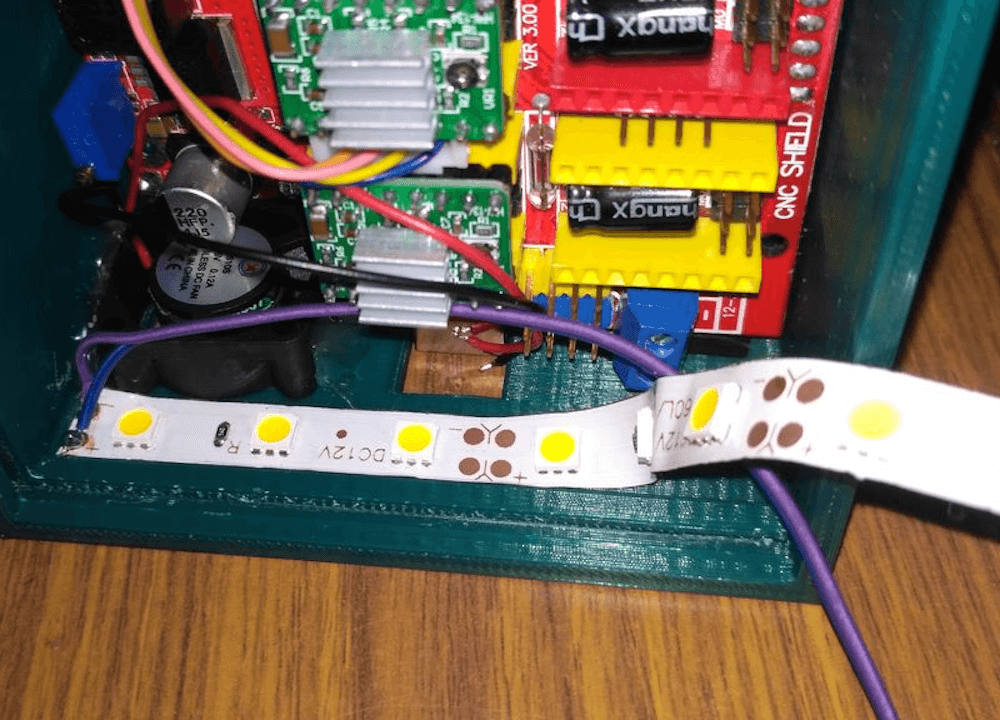

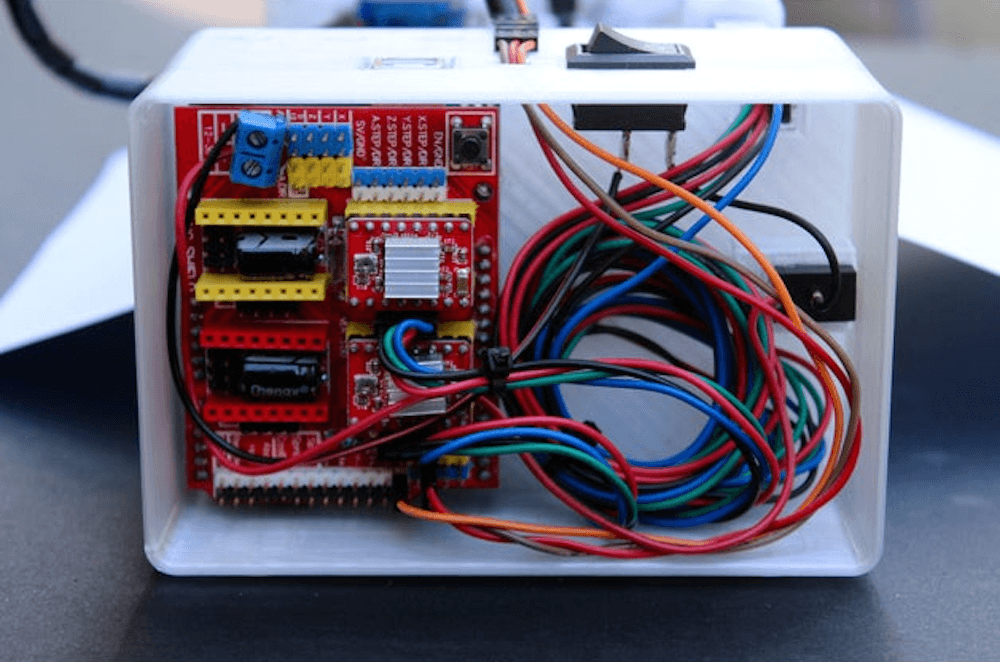

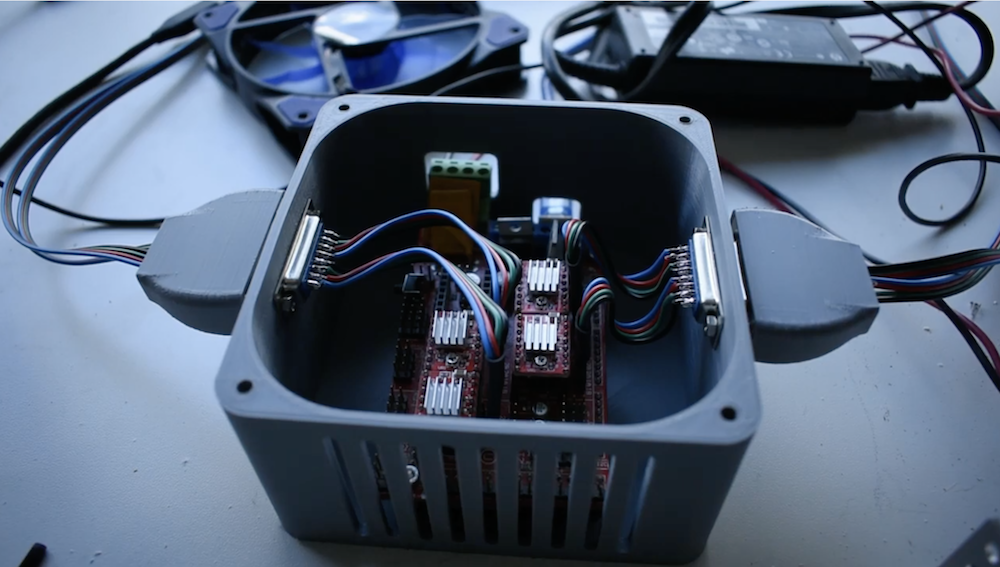

Control is via an Arduino Mega running Grbl, with a RAMPS 1.4 shield.