23

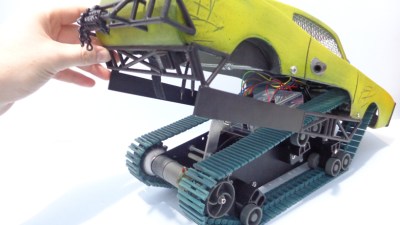

Part of [Gelstronic]’s house has a glass roof. While he enjoys the natural light and warmth, he doesn’t like getting up on a ladder to clean it every time a bird makes a deposit or the rainwater stains build up. He’s tried to make a cleaning robot in the past, but the 25% slope of the roof complicates things a bit. Now, with the addition of stepper motors and grippy tank treads, [Gelstronic] can tell this version of GRawler exactly how far to go, or to stay in one place to clean a spot that’s extra dirty.

GRawler is designed to clean on its way up the roof, and squeegee on the way back down. It’s driven by an Arduino Pro Micro and built from lightweight aluminium and many parts printed in PLA. GRawler also uses commonly-available things, which is always a bonus: the brush is the kind used to clean behind appliances, and the squeegee blade is from a truck-sized wiper. [Gelstronic] can control GRawler’s motors, the brush’s spin, and raise/lower the wiper blade over Bluetooth using an app called Joystick BT Commander. Squeak past the break to see it in action.

As far as we can tell, [Gelstronic] will still have to break out the ladder to place GRawler and move him between panels. Maybe the next version could be tethered, like Scrobby the solar panel-cleaning robot.