10

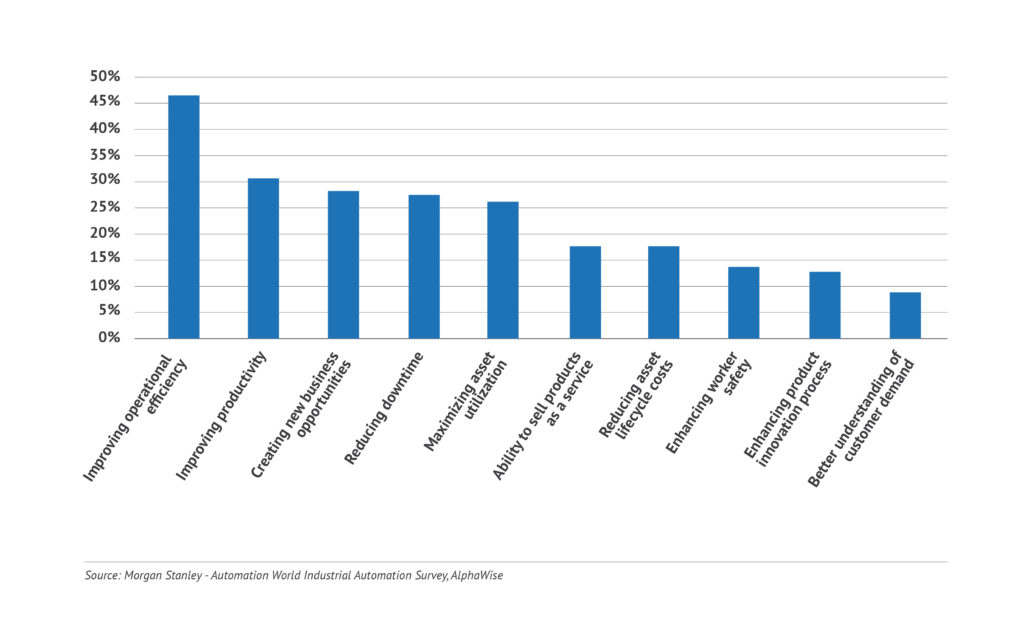

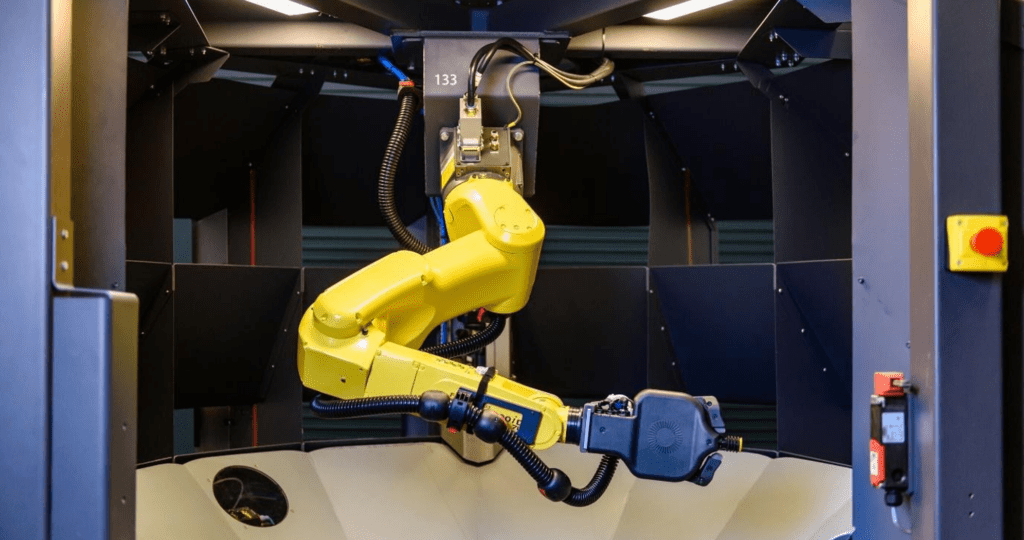

Wevolver’s previous article about the Arduino Pro ecosystem outlined how embedded sensors play a key role in transforming machines and automation devices to Cyber Physical Production Systems (CPPS). Using CPPS systems, manufacturers and automation solution providers capture data from the shop floor and use it for optimizations in areas like production schedules, process control, and quality management. These optimizations leverage advanced data Internet of Things (IoT) analytics over manufacturing datasets, which is the reason why data are the new oil.

Deployment Options for IoT Analytics: From Cloud Analytics to TinyML

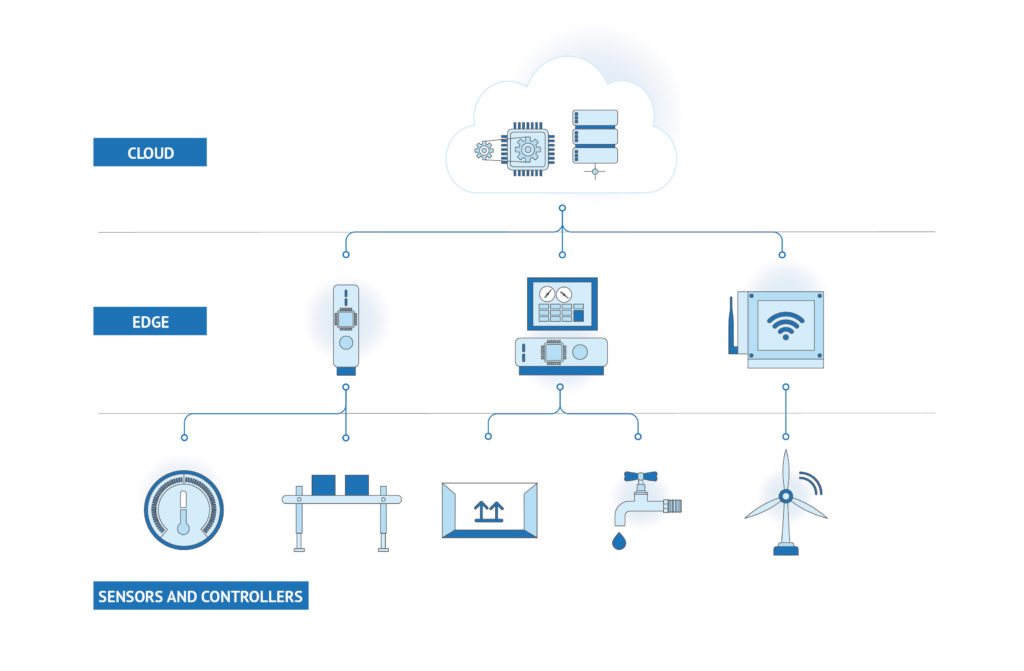

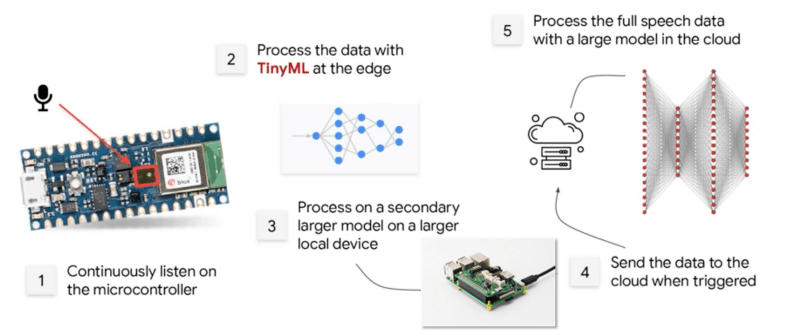

IoT analytics entail statistical data processing and employ Machine Learning (ML) functions, including Deep Learning (DL) techniques i.e., ML based on deep neural networks. Many manufacturing enterprises deploy IoT analytics in the cloud. Cloud IoT analytics use the vast amounts of cloud data to train accurate DL models. Accuracy is important for many industrial use cases like Remaining Useful Life calculation in predictive maintenance. Nevertheless, it is also possible to execute analytics at the edge of the network. Edge analytics are deployed within embedded devices or edge computing clusters at the factory’s Local Area Network (LAN). They are appropriate for real-time use cases that demand low latency such as real-time detection of defects. Edge analytics are more power-efficient than cloud analytics. Moreover, they offer increased data protection as data stays within the LAN.

During the last couple of years, industrial organizations use TinyML to execute ML models within CPU and memory-constrained devices. TinyML is faster, real-time, more power-efficient, and more privacy-friendly than any other form of edge analytics. Therefore, it provides benefits for many Industry 4.0 use cases.

Building TinyML Applications

The process of developing and deploying TinyML applications entails:

- Getting or Producing a Dataset, which is used for training the TinyML model. In this direction, data from sensors or production logs can be used.

- Train an ML or DL Model, using standard tools and libraries like Jupyter Notebooks and Python packages like TensorFlow and NumPy. The work entails Exploratory Data Analysis steps towards understanding the data, identifying proper ML models, and preparing the data for training them.

- Evaluate the Model’s Performance, using the trained model predictions and calculating various error metrics Depending on the achieved performance, the TinyML engineer may have to improve the model and avoid overfitting on the data. Different models must be tested to find the best one.

- Make the Model Appropriate to Run on an Embedded Device, using tools like TensorFlow Lite which provides a “converter” library that turns a model into a space-efficient format. TensorFlow Lite provides also an “interpreter” library that runs the converted model using the most efficient operations for a given device. In this step, a C/C++ sketch is produced to enable on device deployment.

- On-device Inference and Binary Development, which involves the C/C++ and embedded systems development part and produces a binary application for on-device inference.

- Deploying the Binary to a Microcontroller, which makes the microcontroller able to analyse data and derive real-time insights.

Leveraging AutoML for Faster Development with Arduino Pro

Nowadays, Automatic Machine Learning (AutoML) tools are used to develop TinyML on various boards, including Arduino boards. Emerging platforms such as Edge Impulse, Qeexo and SensiML, among others, provide AutoML tools and developers’ resources for embedded ML development. Arduino is collaborating with such platforms as part of their strategy to make complex technologies open and simple to use by anyone.

Within these platforms, users collect real-world sensor data, train ML models on the cloud, and ultimately deploy the model back to an Arduino device. It is also possible to integrate ML models with Arduino sketches based on simple function calls. AutoML pipelines ease the tasks of (re)developing and (re)deploying models to meet complex requirements.

The collaboration between Arduino and ML platforms enables thousands of developers to build applications that embed intelligence in smart devices such as applications that recognize spoken keywords, gestures, and animals. Implementing applications that control IoT devices via natural language or gestures is relatively straightforward for developers who are familiar with Arduino boards.

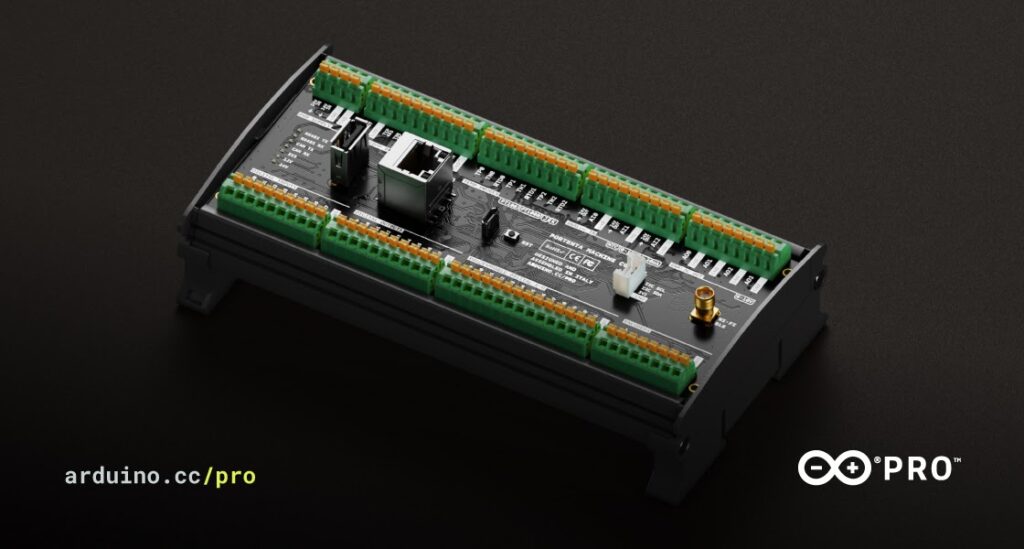

Arduino has recently introduced its new Arduino Pro ecosystem of industrial-grade products and services, which support the full development, production and operation lifecycle from Hardware and Firmware to Low Code, Clouds, and Mobile Apps. The Pro ecosystem empowers thousands of developers to jump into Industry 4.0 development and to employ advanced edge analytics.

Big opportunity at every scale

The Arduino ecosystem provides excellent support for TinyML, including boards that ease TinyML development, as well as relevant tools and documentation. For instance, the Arduino Nano 33 BLE Sense board is one of the most popular boards for TinyML. It comes with a well-known form factor and various embedded sensors. The latter include a 9-axis inertial sensor that makes the board ideal for wearable devices, as well as for humidity and temperature sensors. As another example, Arduino’s Portenta H7 board includes two asymmetric cores, which enables simultaneously runs of high level code such as protocol stacks, machine learning or even interpreted languages (e.g., MicroPython or JavaScript). Furthermore, the Arduino IDE (Integrated Development Environment) provides the means for customizing embedded ML pipelines and deploying them in Arduino boards.

In a Nutshell

ML and AI models need not always to run over powerful clouds and related High Performance Computing services. It is also possible to execute neural networks over tiny memory-limited devices like microcontrollers, which opens unprecedented opportunities for pervasive intelligence. The Arduino ecosystem offers developers the resources they need to ride the wave of Industry 4.0 and TinyML. Arduino boards and the IDE lower the barriers for thousands of developers to engage with IoT analytics for industrial intelligence.

Read the full article on Wevolver.

The post From Embedded Sensors to Advanced Intelligence: Driving Industry 4.0 Innovation with TinyML appeared first on Arduino Blog.