31

There are three types of motors that makers typically consider: stepper motors, servo motors, and DC motors (either brushed or brushless). Stepper motors are great when you need high precision and torque, but tend to have jerky movement. DC motors work well for high speed movement that doesn’t need any rotational accuracy. Servo motors are somewhat of a compromise between the two. But Aaed Musa’s 3D-printed continuous rotation servo motor is even better, because it is fast, smooth, and accurate.

This motor works like a standard servo motor, so you can set it to any desired position. But it features continuous rotation, an integrated gearbox to improve torque, very smooth movement, and a magnetic encoder to ensure accurate positioning. As you can see in the video, it responds almost instantly, moves fast, and isn’t jittery at all. Because all of the mechanical parts are 3D-printed, durability may be a concern. But otherwise this is a very attractive option.

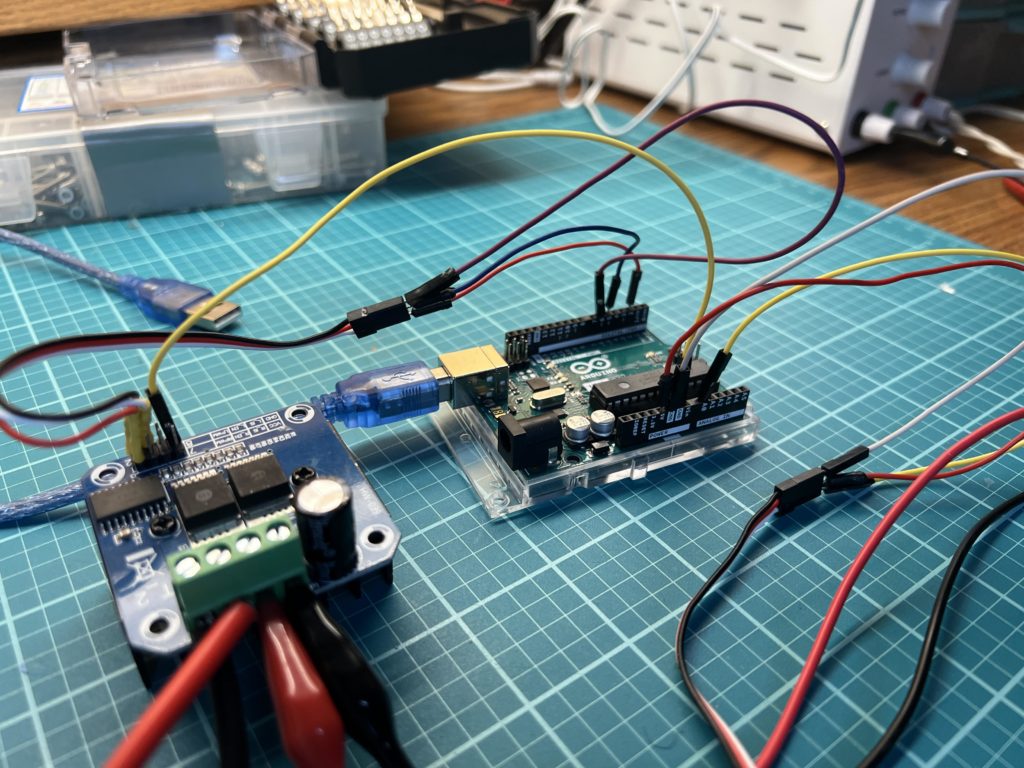

Musa designed this to work with a 600RPM DC gear motor. He then further reduced the output with a 3D-printed gearbox designed in Autodesk Fusion 360. An Arduino Uno board controls the motor through a BTS7960 motor driver and monitors the position with an AS5600 magnetic encoder. The total build cost should be around $30, not including the cost of the Arduino. More details on the project can be found in Muse’s Instructables write-up.

The post 3D-printed continuous rotation servo motor is super smooth appeared first on Arduino Blog.