05

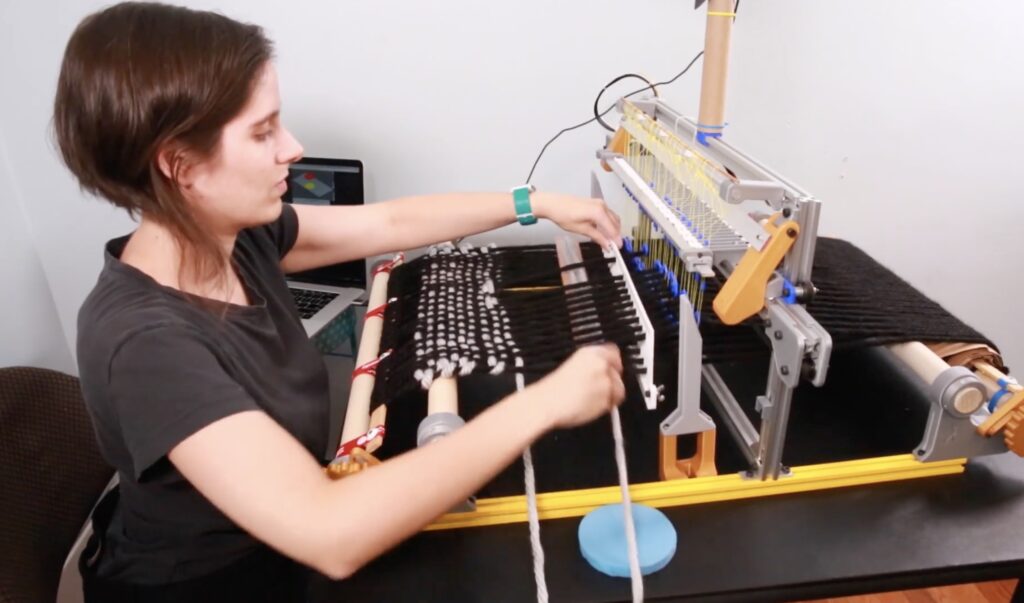

Jacquard looms revolutionized the weaving process by independently controlling each heddle’s position. That made it possible to weave complex patterns. But modern Jacquard looms are very expensive, because they require a solenoid or other means of actuation for each and every heddle. Lea Albaugh and her team at Carnegie Mellon University found an affordable way to build a Jacquard loom from 3D printer parts — including an Arduino-based controller.

The key development for this Jacquard loom was a special bistable switch for each heddle. Those switches keep their heddles in the position in which they were last set. That makes it possible to set the heddle positions sequentially, instead of simultaneously with a multitude of solenoids. All of the heddle positions can be set by a single solenoid, which slides back and forth across the loom. This keeps costs down and makes it possible to build a Jacquard loom for about $200 using common 3D printer components.

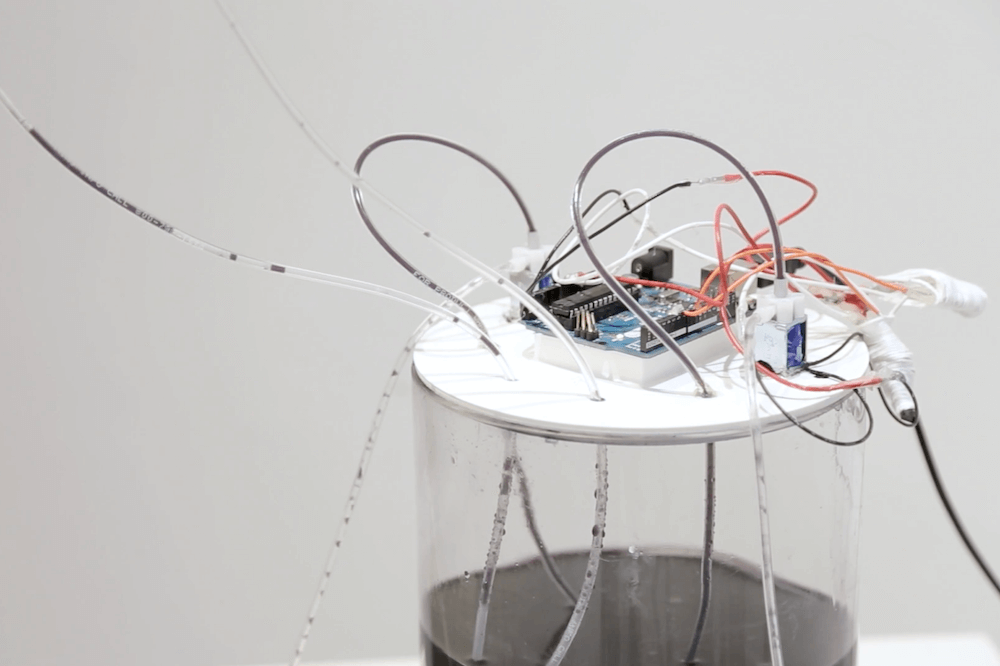

The frame of this loom was built using aluminum extrusion and 3D-printed brackets. The linear rails and stepper motors are the same type that you would find in a 3D printer. The controller, a RAMPS 1.4 shield on an Arduino Mega board, is also typically used for 3D printing. The Arduino receives G-code commands from a connected computer, which monitors the loom through a commodity webcam running OpenCV computer vision software. While the loom still requires hand weaving, the automated heddle positioning allows for the quick and accurate production of complex patterns by hobbyists at home.

The post Weaving just got a lot better thanks to this Arduino-controlled Jacquard loom appeared first on Arduino Blog.