26

We all know how annoying a ceiling fan can be when it isn’t balanced well and that annoyance perfectly demonstrates the necessity of a good, sturdy bearing. A ceiling fan’s bearing needs to allow for smooth rotational motion with as little friction as possible, while completely constraining movement in every other axis. Those properties make a ceiling base a surprisingly good starting point for a SCARA, as demonstrated in tuenhidiy’s recent Instructables write-up.

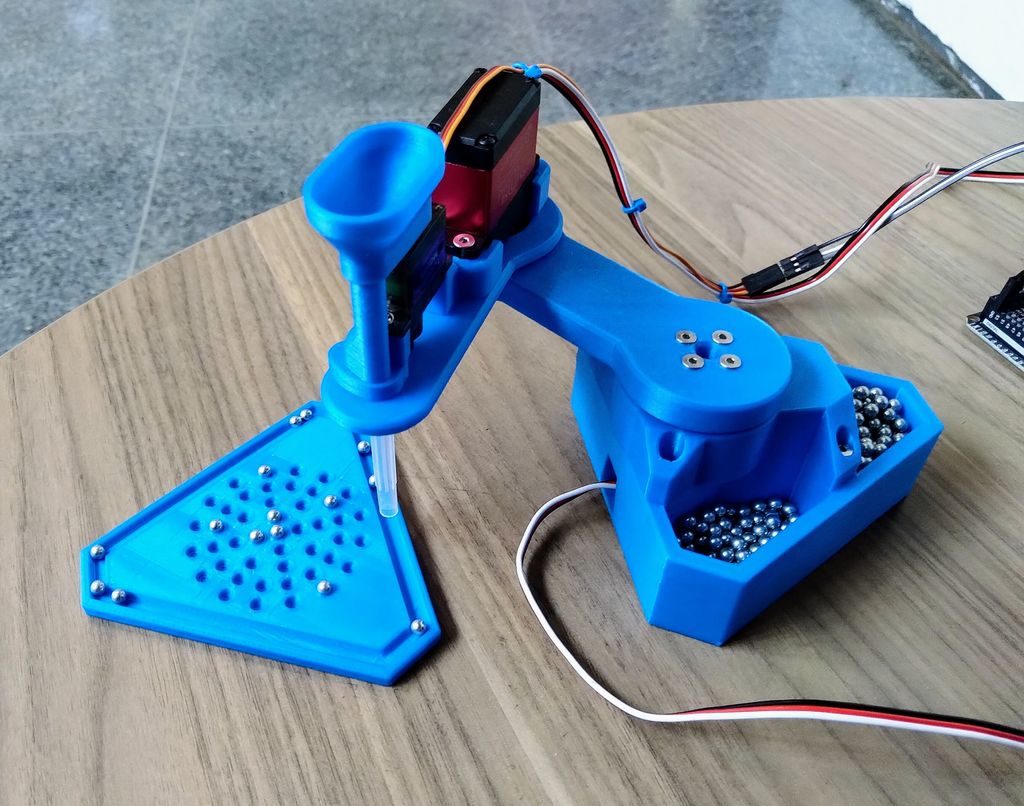

In their tutorial, tuenhidiy refers to this as a “Spaceship Scara Arm.” It isn’t exactly clear why they chose the “spaceship” terminology, but it is similar to a conventional SCARA (Selective Compliance Assembly Robot Arm) — just one with only two degrees of freedom (DOF).

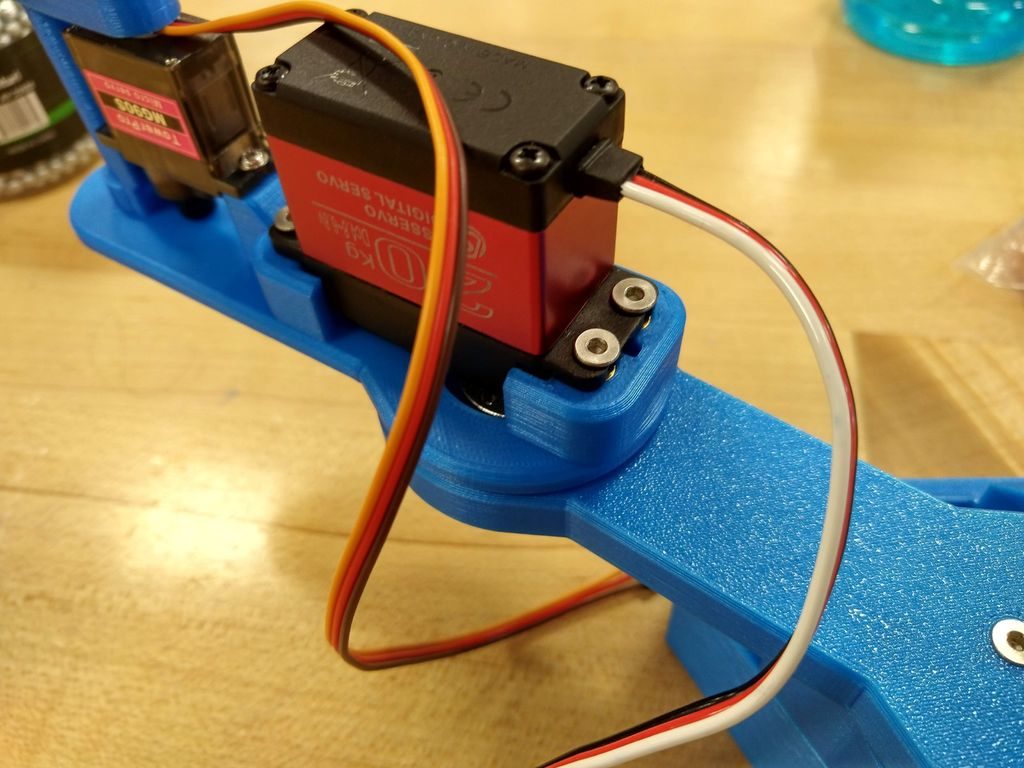

The entire point of a SCARA is that it is fully constrained, except for rotation around the Z axis at each joint. After their ceiling fan broke, tuenhidiy noticed that the fan’s base with its beefy bearing would be perfect for this application. They took that, added a couple of stepper motors and belts, some aluminum extrusion, and a couple more bearings to create this simple SCARA.

An Arduino UNO Rev3 board controls those motors through a CNC Shield V3. Grbl firmware makes it easy to control the positions of the motors using just about any software a user could possibly want. Some simple calculations regarding the arm’s geometry and gear ratios should let appropriate software determine exactly where it is in space. For a demonstration, tuenhidiy added a DC solenoid for its magnetic capabilities. But anyone replicating this project can add their own end effector to suit their needs.

The post Ceiling fan becomes a “spaceship” SCARA robot arm appeared first on Arduino Blog.