Dec

02

02

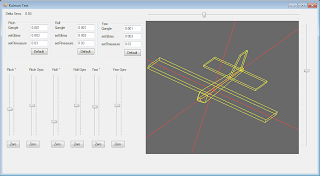

Yellow Plane 2 with inverted V tail software modified and tested stability gyros

2.4GHz, arduino, arduino nano, dtb850, FPV, inverted vee tail, scratch build, Turnigy dlux 30A SBEC Brushless Speed Controller, twin boom, xBee, XBee Explorer Regulated, XBee Pro 60mW U.FL Connection - Series 1 Comments Off on Yellow Plane 2 with inverted V tail software modified and tested stability gyros

New Code

Kalman Filter

New parts

Turnigy L3010C-1300kv (420w)

H-KING 50A Fixed Wing Brushless Speed Controller

ZIPPY Compact 2700mAh 3S 25C Lipo Pack

HobbyKing 929MG Metal Gear Servo 2.2kg/ 12.5g/ 0.10sec

Dimentions

AUW 1521 Grams Wing loading 14.83 oz/ft² power to weight 270 Watts A Kg should perform much better than Yellow plane one.

Kalman Filter

This is the code in the main loop UpdateServos()

unsigned long msDelta = LastMicros - micros();

LastMicros = micros();

//Measure time since last cycle

double dt = (double)msDelta / 1000000.0;

// The angle should be in degrees and the rate should be in degrees per second and the delta time in seconds

double X_Angle = (double)AnIn[0];

double X_Rate = (double)AnIn[4];

double Kalman_X = kalman[0].getAngle(X_Angle, X_Rate, dt);

double Y_Angle = (double)AnIn[1];

double Y_Rate = (double)AnIn[5];

double Kalman_Y = kalman[1].getAngle(Y_Angle, Y_Rate, dt);

double Z_Angle = (double)AnIn[2];

double Z_Rate = (double)AnIn[6];

double Kalman_Z = kalman[2].getAngle(Z_Angle, Z_Rate, dt);

/* Copyright (C) 2012 Kristian Lauszus, TKJ Electronics. All rights reserved.

This software may be distributed and modified under the terms of the GNU

General Public License version 2 (GPL2) as published by the Free Software

Foundation and appearing in the file GPL2.TXT included in the packaging of

this file. Please note that GPL2 Section 2[b] requires that all works based

on this software must also be made publicly available under the terms of

the GPL2 ("Copyleft").

Contact information

-------------------

Kristian Lauszus, TKJ Electronics

Web : http://www.tkjelectronics.com

e-mail : kristianl@tkjelectronics.com

*/

#ifndef _Kalman_h

#define _Kalman_h

class Kalman {

public:

Kalman() {

/* We will set the varibles like so, these can also be tuned by the user */

Q_angle = 0.001;

Q_bias = 0.003;

R_measure = 0.03;

bias = 0; // Reset bias

P[0][0] = 0; // Since we assume tha the bias is 0 and we know the starting angle (use setAngle), the error covariance matrix is set like so - see: http://en.wikipedia.org/wiki/Kalman_filter#Example_application.2C_technical

P[0][1] = 0;

P[1][0] = 0;

P[1][1] = 0;

};

// The angle should be in degrees and the rate should be in degrees per second and the delta time in seconds

double getAngle(double newAngle, double newRate, double dt) {

// KasBot V2 - Kalman filter module - http://www.x-firm.com/?page_id=145

// Modified by Kristian Lauszus

// See my blog post for more information: http://blog.tkjelectronics.dk/2012/09/a-practical-approach-to-kalman-filter-and-how-to-implement-it

// Discrete Kalman filter time update equations - Time Update ("Predict")

// Update xhat - Project the state ahead

/* Step 1 */

rate = newRate - bias;

angle += dt * rate;

// Update estimation error covariance - Project the error covariance ahead

/* Step 2 */

P[0][0] += dt * (dt*P[1][1] - P[0][1] - P[1][0] + Q_angle);

P[0][1] -= dt * P[1][1];

P[1][0] -= dt * P[1][1];

P[1][1] += Q_bias * dt;

// Discrete Kalman filter measurement update equations - Measurement Update ("Correct")

// Calculate Kalman gain - Compute the Kalman gain

/* Step 4 */

S = P[0][0] + R_measure;

/* Step 5 */

K[0] = P[0][0] / S;

K[1] = P[1][0] / S;

// Calculate angle and bias - Update estimate with measurement zk (newAngle)

/* Step 3 */

y = newAngle - angle;

/* Step 6 */

angle += K[0] * y;

bias += K[1] * y;

// Calculate estimation error covariance - Update the error covariance

/* Step 7 */

P[0][0] -= K[0] * P[0][0];

P[0][1] -= K[0] * P[0][1];

P[1][0] -= K[1] * P[0][0];

P[1][1] -= K[1] * P[0][1];

return angle;

};

void setAngle(double newAngle) { angle = newAngle; }; // Used to set angle, this should be set as the starting angle

double getRate() { return rate; }; // Return the unbiased rate

/* These are used to tune the Kalman filter */

void setQangle(double newQ_angle) { Q_angle = newQ_angle; };

void setQbias(double newQ_bias) { Q_bias = newQ_bias; };

void setRmeasure(double newR_measure) { R_measure = newR_measure; };

private:

/* variables */

double Q_angle; // Process noise variance for the accelerometer

double Q_bias; // Process noise variance for the gyro bias

double R_measure; // Measurement noise variance - this is actually the variance of the measurement noise

double angle; // The angle calculated by the Kalman filter - part of the 2x1 state matrix

double bias; // The gyro bias calculated by the Kalman filter - part of the 2x1 state matrix

double rate; // Unbiased rate calculated from the rate and the calculated bias - you have to call getAngle to update the rate

double P[2][2]; // Error covariance matrix - This is a 2x2 matrix

double K[2]; // Kalman gain - This is a 2x1 matrix

double y; // Angle difference - 1x1 matrix

double S; // Estimate error - 1x1 matrix

};

#endif

New parts

Turnigy L3010C-1300kv (420w)

H-KING 50A Fixed Wing Brushless Speed Controller

ZIPPY Compact 2700mAh 3S 25C Lipo Pack

HobbyKing 929MG Metal Gear Servo 2.2kg/ 12.5g/ 0.10sec

Dimentions

1200 mm Wing span

280 mm cord

Missing battery and camera box have a design which should weigh 140 grams empty.

The assembly shown below weighs 684 Grams no motor or electronics.

Electronics shown weigh 110 grams ESC Arduino board, Xbee, antenna and Gyro board

Motor and prop another 120 Gram

The code with the mixing and stability feedback, all looks Ok on the bench

void UpdateServos()

{

//Digital inputs TX code helper

//TxVal[8] |= (digitalRead(5) << 0);//joy 2 push

//TxVal[8] |= (digitalRead(6) << 1);//pb

//TxVal[8] |= (digitalRead(7) << 2);//slide

//TxVal[8] |= (digitalRead(8) << 3);//toggle

//Throttle TxVal[1]

//Rotary pot TxVal[2]

//Joy 1 X TxVal[3]

//Joy 1 Y TxVal[4]

//Joy 2 X TxVal[5]

//Joy 2 Y TxVal[6]

//rssi TxVal[7]

//digital TxVal[8]

//micros() TxVal[9]

//Use the pot as the gain for all channels for now

float GainPot = (float)(TxVal[2]) * 0.001f;

//Get the target values from the TX

int PitchTarg = (TxVal[3] / 10);

int RollTarg = (TxVal[4] / 10);

int YawTarg = (TxVal[6] / 10);

//Prime the Target WOZ values

if(PitchTargWOZ == 9999)

PitchTargWOZ = PitchTarg;

if(RollTargWOZ == 9999)

RollTargWOZ = RollTarg;

if(YawTargWOZ == 9999)

YawTargWOZ = YawTarg;

//Get the Centered target values

float PitchTargCentred = (float)(PitchTarg - PitchTargWOZ);

float RollTargCentred = (float)(RollTarg - RollTargWOZ);

float YawTargCentred = (float)(YawTarg - YawTargWOZ);

//Calculate gains

float PitchGain = GainPot * 1.0f;

float RollGain = GainPot * 1.0f;

float YawGain = GainPot * 1.0f;

//Get Gyro values

float PitchGyro = (float)(AnIn[2] - AnInWOZ[2]);

float RollGyro = (float)(AnIn[1] - AnInWOZ[1]);

float YawGyro = (float)(AnIn[0] - AnInWOZ[0]);

//Calc P error

float PitchError = (float)PitchTargCentred + PitchGyro;

float RollError = (float)RollTargCentred + RollGyro;

float YawError = (float)YawTargCentred + YawGyro;

//Apply gains

int PitchTrim = (int)(PitchError * PitchGain);

int RollTrim = (int)(RollError * RollGain);

int YawTrim = (int)(YawError * YawGain);

//Constaring trim authority

PitchTrim = constrain(PitchTrim, -30, 30);

RollTrim = constrain(RollTrim, -30, 30);

YawTrim = constrain(YawTrim, -30, 30);

//Dump the trim value

if((TxVal[9] & 0x4) == 0)

{

PitchTrim = 0;

RollTrim = 0;

YawTrim = 0;

}

//Calc flap anglke

int Flaps = 0;

//Apply flaps

if((TxVal[9] & 0x8) == 0)

Flaps = -25;

//Throttle

val = TxVal[1] / 10;

val = map(val, 1, 179, 30, 179);

val = constrain(val, 1, 165); // scale it to use it with the servo (value between 0 and 180)

servo[0].write(val); // sets the servo position according to the scaled value

//Vee tail

//Left Elevator Joy 1 Y TxVal[4]

val = (YawTarg + YawTrim) + (PitchTargCentred + PitchTrim);

val = constrain(val, 15, 165);

val = map(val, 0, 179, 135, 45); // scale it to use it with the servo (value between 0 and 180)

servo[1].write(val); // sets the servo position according to the scaled value

//Right Elevator Joy 1 Y TxVal[4]

val = (YawTarg + YawTrim) - (PitchTargCentred + PitchTrim);

val = constrain(val, 15, 165);

val = map(val, 0, 179, 135, 45); // scale it to use it with the servo (value between 0 and 180)

servo[2].write(val); // sets the servo position according to the scaled value

//Left Flaperon

val = 90 + (RollTargCentred + Flaps) + RollTrim;

val = constrain(val, 15, 165);

val = map(val, 0, 179, 165, 15); // scale it to use it with the servo (value between 0 and 180)

servo[3].write(val); // sets the servo position according to the scaled value

//Right Flaperon

val = 90 + (RollTargCentred - Flaps) + RollTrim;

val = constrain(val, 15, 165);

val = map(val, 0, 179, 165, 15); // scale it to use it with the servo (value between 0 and 180)

servo[4].write(val); // sets the servo position according to the scaled value

//Joy 2 x nose Wheel

val = (TxVal[6] / 10);

val = map(val, 0, 179, 55, 125);

servo[5].write(val); // sets the servo position according to the scaled value

}

14% Clark Y more or les given the limitations of the Coroplast