25

When you think of automation, what’s the first image that comes to mind?

For many of us, it’s a robot. From the blocky, square-headed characters of sci-fi comic fame to household more complex creations like the Replicants of Blade Runner — robots have captured our collective imagination for a long time.

It’s no surprise, then, that lots of Arduino users eventually set out to build a robot of their own.

In this article, we’ll look at how to build your own robot with Arduino and share some project examples from other makers.

What exactly is a robot?

The term “robot” can cover a lot of potential meanings, so let’s agree on a definition.

Here’s what the Oxford Dictionary says:

“(especially in science fiction) a machine resembling a human being and able to replicate certain human movements and functions automatically.”

It’s a good start, but do all robots resemble humans? Here’s Oxford’s second definition:

“a machine capable of carrying out a complex series of actions automatically, especially one programmable by a computer.”

This seems more accurate since it encompasses things like construction robots, robotic pets, and robotic vehicles.

Humans have been attempting to build robots for centuries, although most of our success has taken place within the last few decades. Today, thanks to advancements in hardware and automation technology, almost anyone can build their own robots at home.

What do you need to build a robot?

Building your own robot might seem like an unimaginably complex task. After all, aren’t robots the stuff of sci-fi movies and leaked military prototypes?

The good news is that building a robot doesn’t have to be a monumental undertaking, and can in fact be done with some fairly simple and easily obtained components.

Here’s what you’ll need:

- Some simple components like wheels, sensors, and switches (this will vary greatly depending on the type of robot you’re planning to build)

- Some basic coding and automation skills (you don’t need to be a coding wizard)

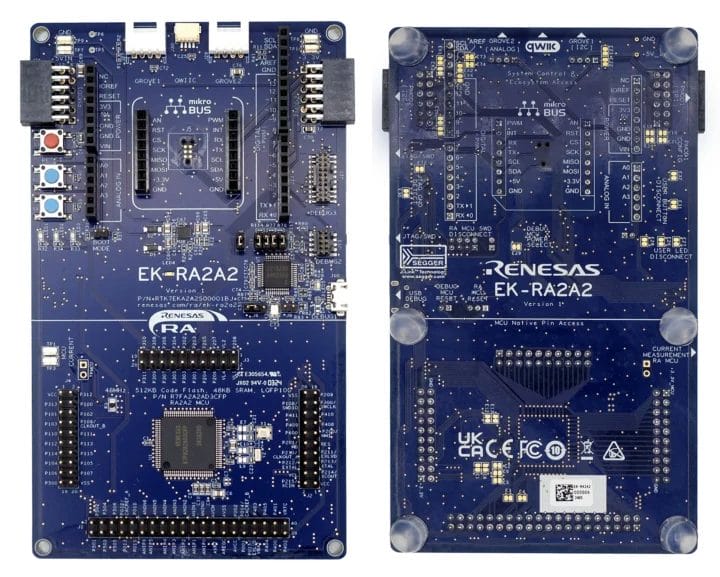

- A microcontroller like the Arduino UNO R4, for example.

This is, of course, just a starting point. You can build a fairly simple robot, or you can ramp up the complexity and sophistication as much as you like — the sky really is the limit here. For beginners, though, you can find everything you need at the hardware store.

Explore Arduino robots

With Arduino’s products and other components, it’s possible to build your own robots more easily than ever before.

We need to look no further than the Arduino Project Hub to find a ton of inspiring ideas. Let’s explore a few.

Line-following robot

Robots don’t have to be ultra-complex humanoid feats of engineering.

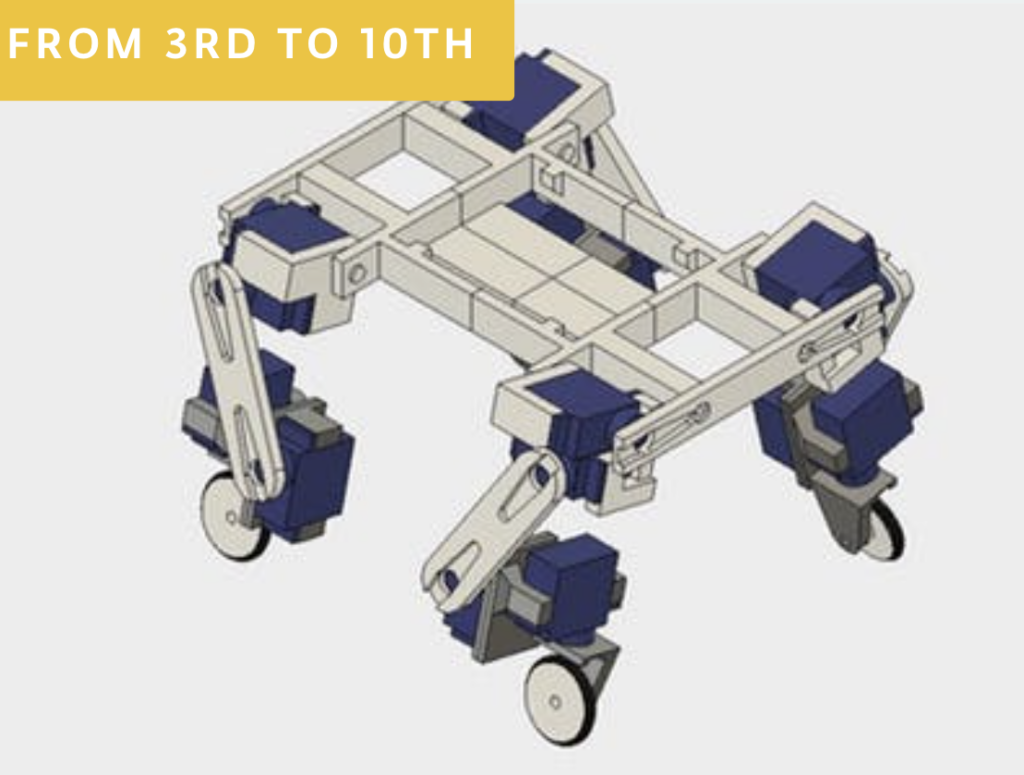

In fact, if you’re just getting started with robotics, it helps to keep things simple. Check out this great example — it’s a simple, car-shaped robot designed to follow a colored line on the floor.

The robot constantly monitors data from its infrared sensors in real time and adjusts movement based on feedback, ensuring it never strays from the line.

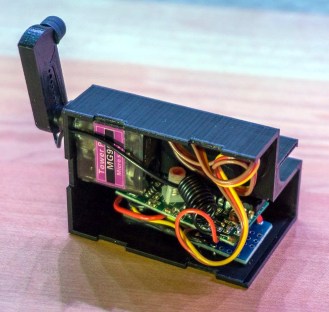

If this kind of project interests you, you’ll love the upcoming Arduino Alvik, which will have a line-follower functionality. Alvik’s user-friendly interface makes MicroPython coding and robotics project development easier than ever, making learning and creating a breeze.

Alvik is also equipped with a range of sensors including a ToF distance sensor, line follower array, color sensor, and more. It’s especially impressive when it comes to swiftly detecting and navigating obstacles and colors.

Join the waiting list here to be first in line for updates about Arduino Alvik.

A piano-playing robot

Did you think playing music was a uniquely human trait?

Well… think again — this musically-inclined robot is capable of controlling piano keys automatically. The device was able to play piano keys 1,875 times in the space of a minute, beating the human world record by a significant margin.

The project used a range of tools including solenoids and a custom-designed Java software interface.

A chess-playing robot arm

Robots have been giving us humans a run for our money in the world of chess for quite some time.

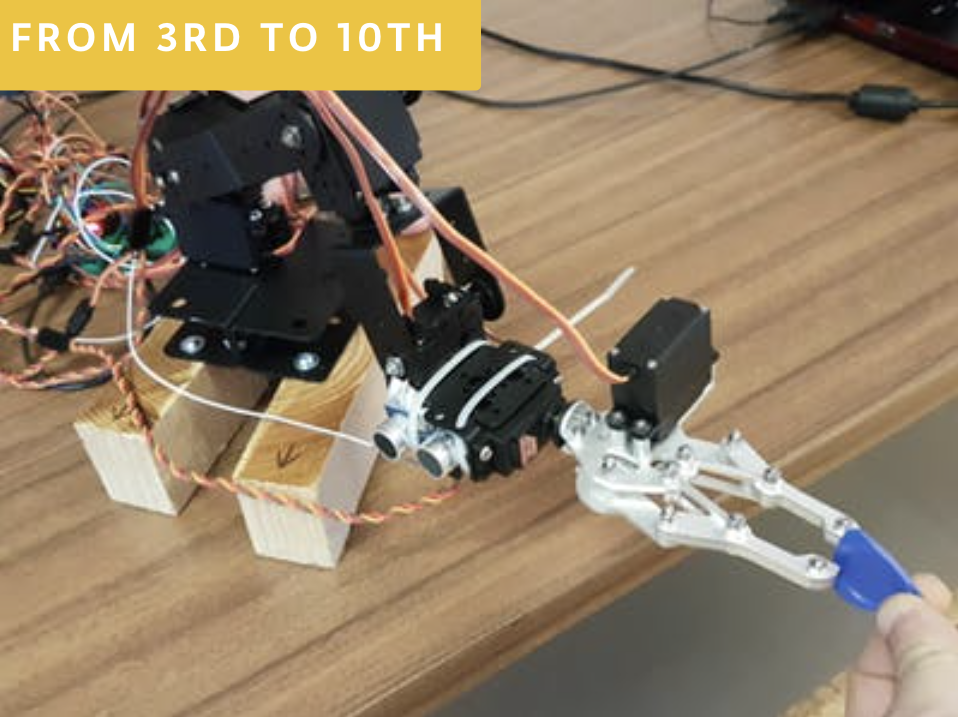

For a new spin on the machines vs. humans saga, take a look at this robotic arm capable of physically moving the chess pieces.

The arm was created using a 3D printer and works by using a visual recognition system to watch the opponent’s move and then formulate a response.

One of the most interesting things about this robot is the code used for move recognition. Because the robot uses visual recognition to follow the human’s moves, there’s no need for additional complex hardware like reed switches to be built into the chessboard, unlike other chess-playing robots.

Stay tuned for Robotics Week!

If you have a passion for building robots or just want to learn more about this topic, you’ll love Robotics Week, which takes place this year from April 6th-13th.

It’s a full week of events — many of which are virtual — all centered around robotics and STEM.

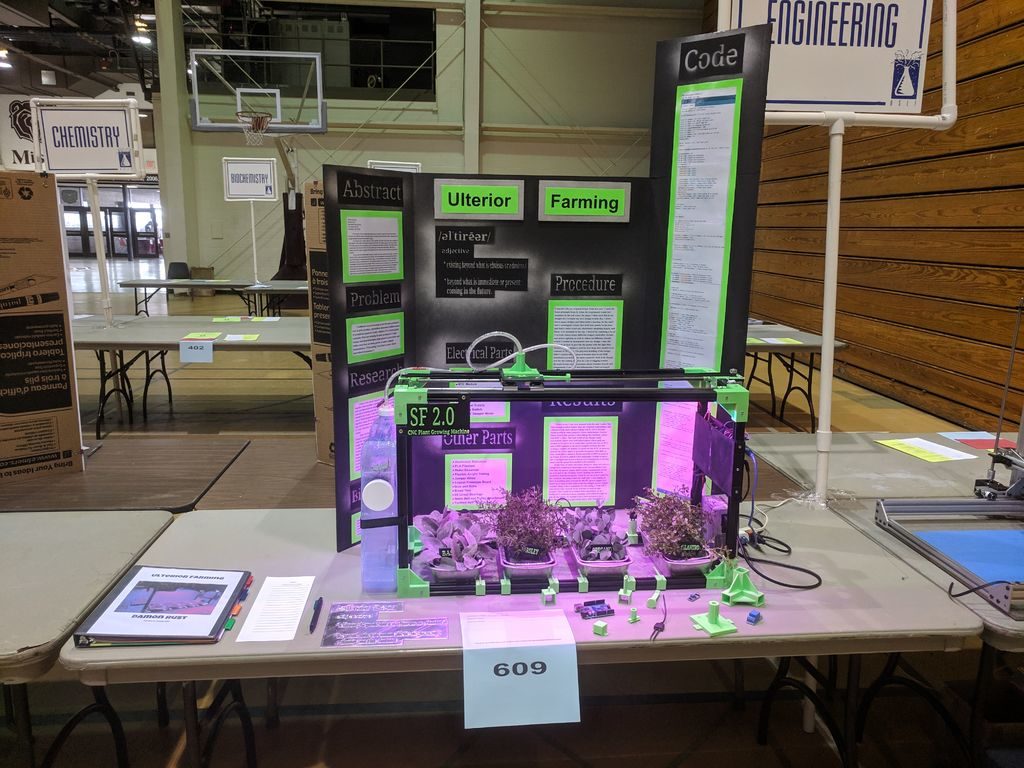

And if that’s not enough for you, this year’s Control Automation Day will focus on the theme of robotics: register today to see Arduino’s session on March 26th, “Arduino Pro Opens the Door to Robot Control for Agriculture, Biotech, and Manufacturing,” showcasing a success story based on the Portenta Machine Control by “Robotics for the Real World” provider R2 labs.

In the meantime, visit our Project Hub for more inspiration — where you can search by category and difficulty level. And don’t forget to share your own projects with our community!

The post Can I build my own robot with Arduino? appeared first on Arduino Blog.