22

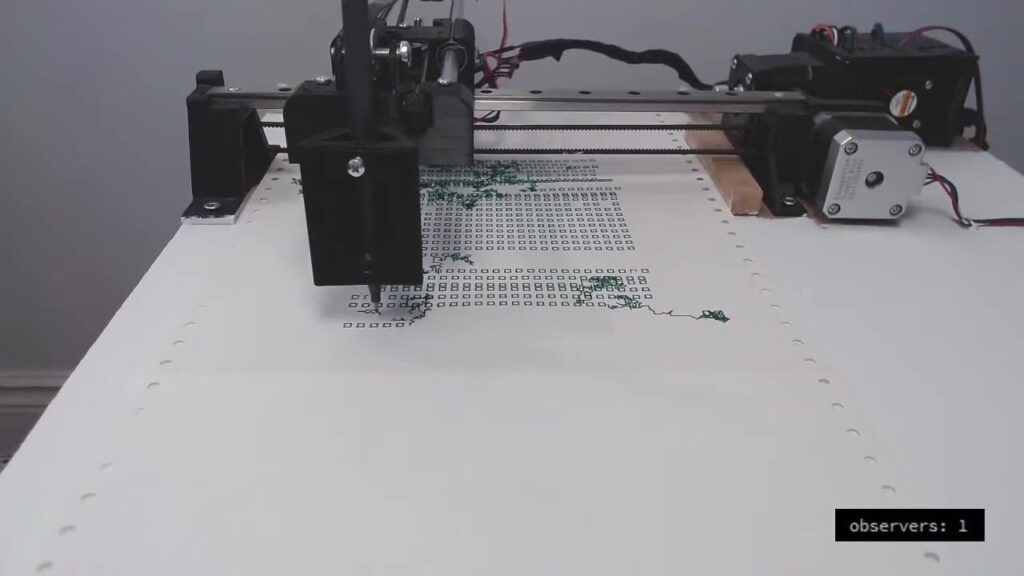

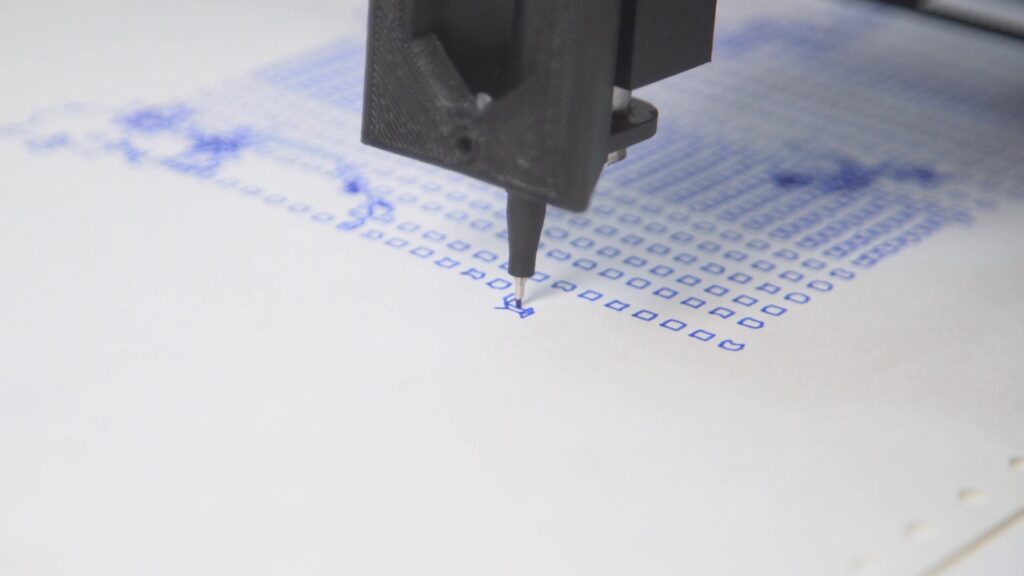

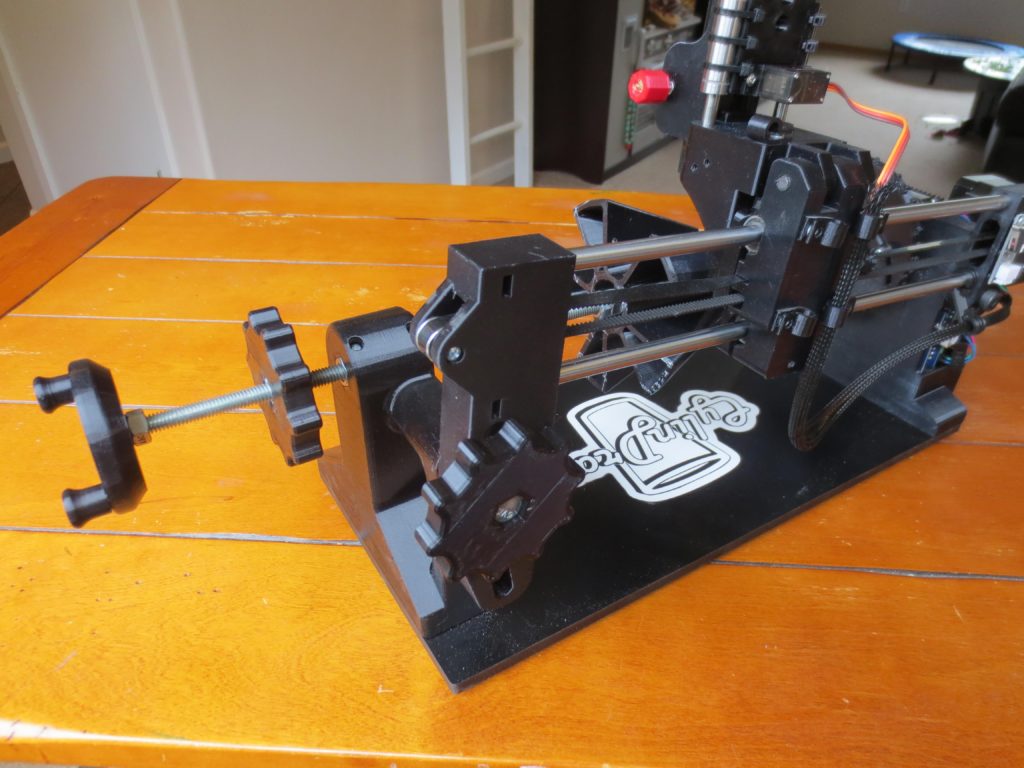

Robots come in all shapes and sizes, but one of the most popular styles for industrial applications is the SCARA (Selective Compliance Assembly Robot Arm). These have multiple degrees of freedom, each of which rotates around the vertical Z axis. But they’re otherwise constrained, which can have advantages for certain applications. For example, they tend to have relatively high payload capacities. If you’re on a budget but want to dip your toes in, tuenhidiy’s SCARA plotter is a great way to start.

This is a follow-up to tuenhidiy’s previous SCARA design from a couple of years ago. The new version is more robust and includes a homing feature, which is important for repeatability. This is set up as a plotter and the firmware reflects that, but it would be possible to adapt the mechanical design for other purposes.

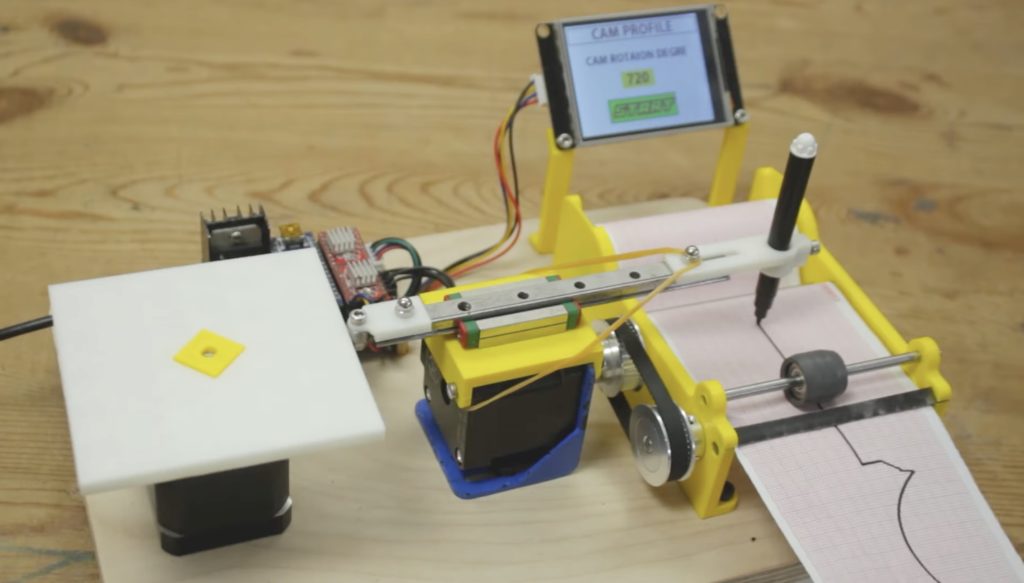

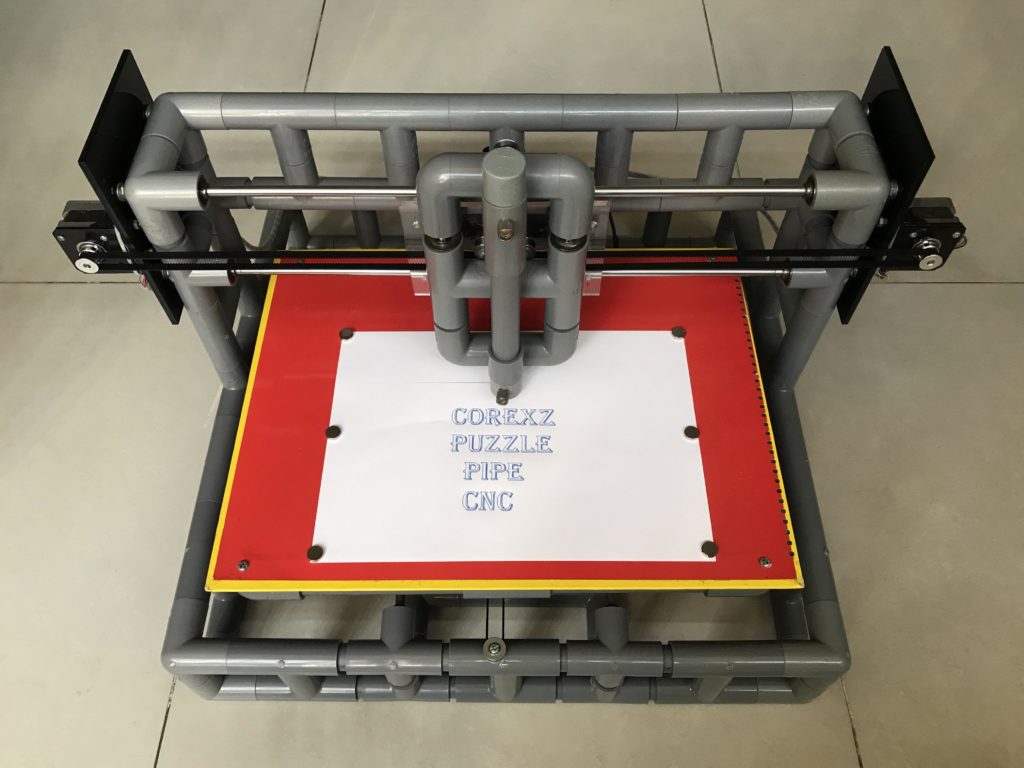

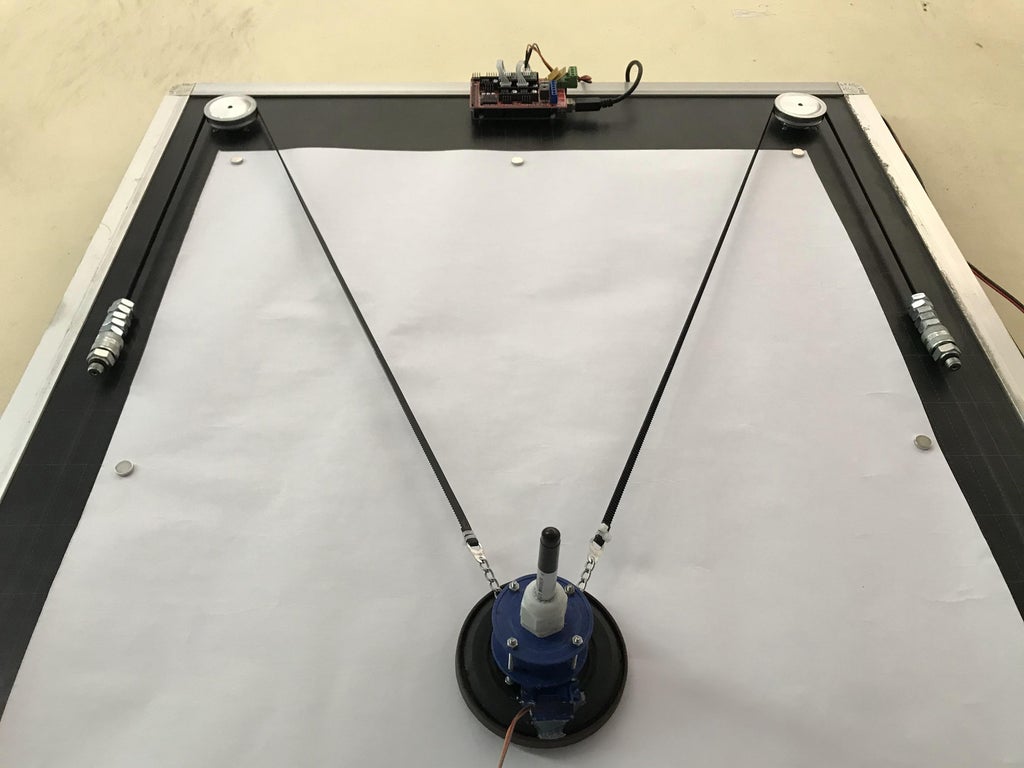

To keep costs down, most of the structure is PVC pipe. Stepper motors provide actuation via GT2 timing belts and pulleys. An Arduino Mega 2560 board controls those steppers through a RAMPS 1.4 board with A4988 stepper drivers. An interface module with a 2004 LCD, rotary encoder, buzzer, and button lets the user start jobs.

In this case, those jobs are G-code files containing the movement commands to reproduce the drawings. That works because the Arduino runs Marlin firmware (popular in the 3D printing community). The use of Marlin made homing easy and it accepts g-code that users can create with most of the standard software tools.

The post Building your own affordable SCARA plotter with Arduino appeared first on Arduino Blog.