23

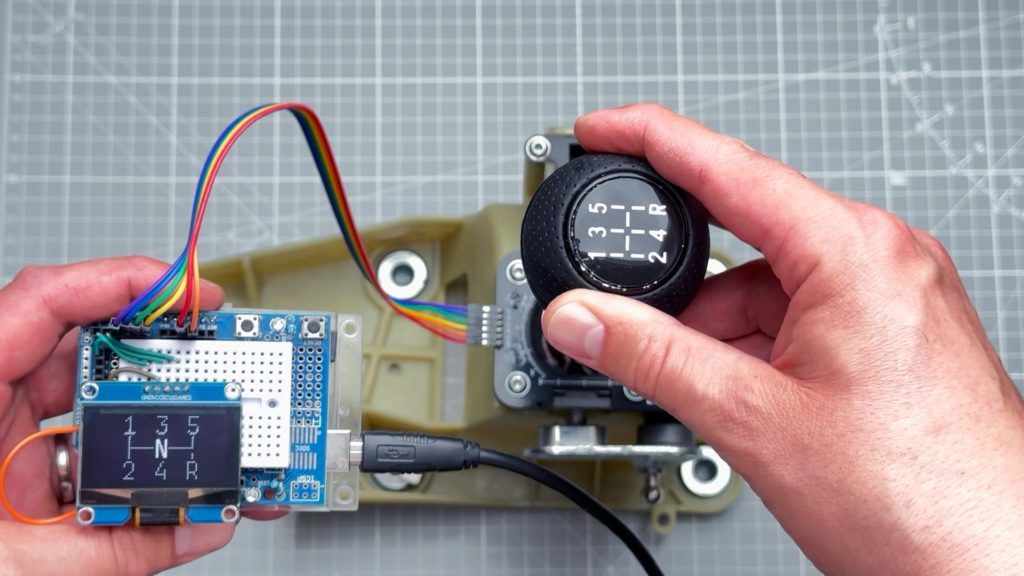

We recently covered Vaclav Krejci’s stick shift project, in which he designed a board that surrounds the shift lever and uses Hall effect sensors to detect its position. It then displayed the current gear on a small OLED screen. The idea was that the user could mount that screen wherever they wanted on the dashboard or center console. But now Krejci is back with a more satisfying solution: an LED display built into the shifter knob itself.

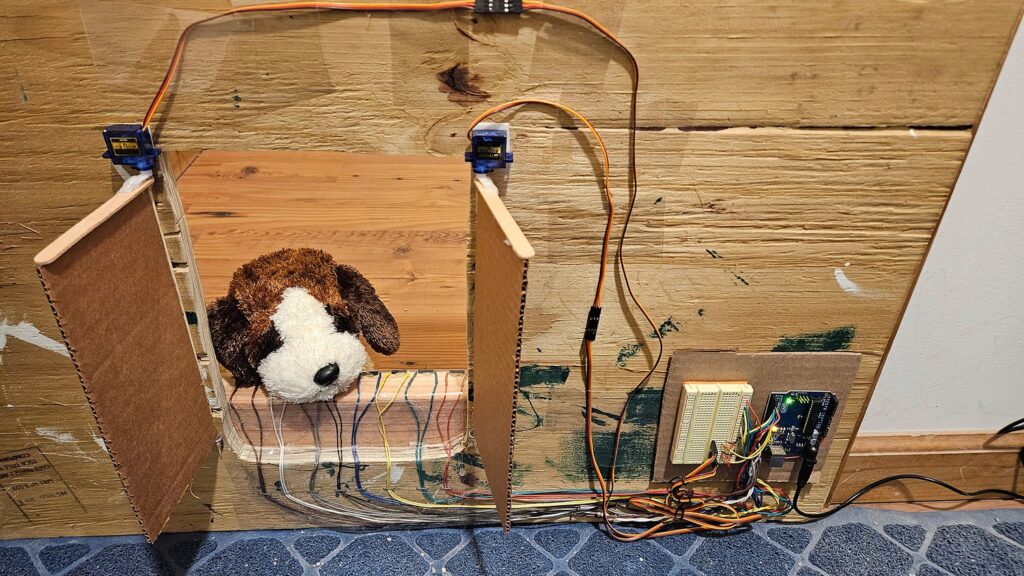

The rest of the hardware, aside from the display, is the same. A custom PCB surrounds the shift lever and contains the Hall effect sensors. Jumper cables connect those to a shield on an Arduino UNO Rev3, which looks at the signals from the sensors and calculates the approximate position of a permanent magnet attached to the shift lever. That position tells the Arduino the current gear.

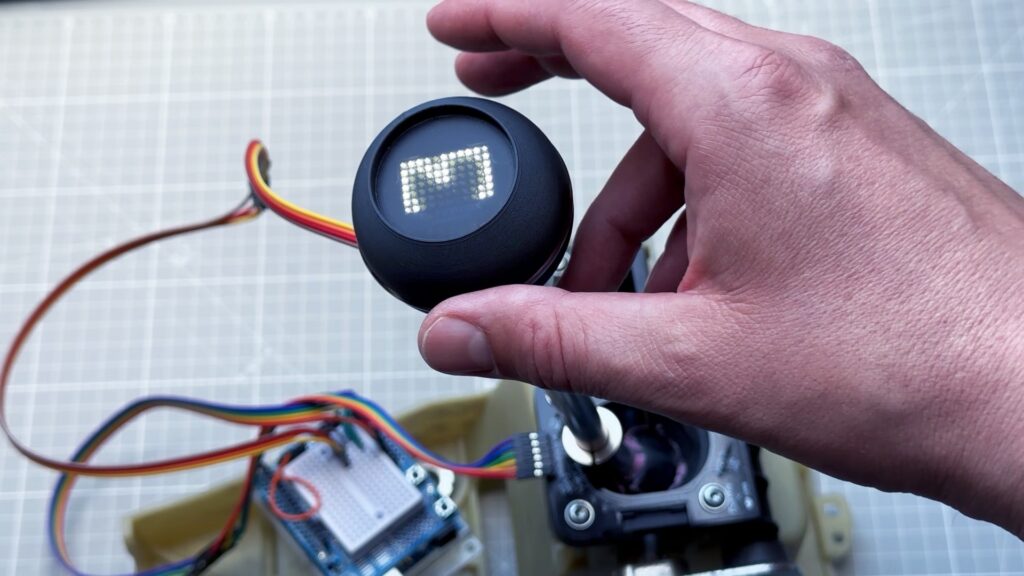

The difference is in how it displays the gear to the user. Before, it was a loose OLED screen. Now, it is a bright Pimoroni 7×11 LED matrix display integrated into the shifter knob. The knob is an inexpensive aftermarket model that Krejci modified for this project. He removed the top half of the knob and replaced it with a 3D-printed version with a cavity where the LED matrix can sit. A sheet of tinted translucent plastic helps to diffuse the light and hide everything else.

This looks absolutely fantastic and would be really cool to see in a car.

The post DIY shifter knob gets a beautiful integrated LED gear indicator appeared first on Arduino Blog.