20

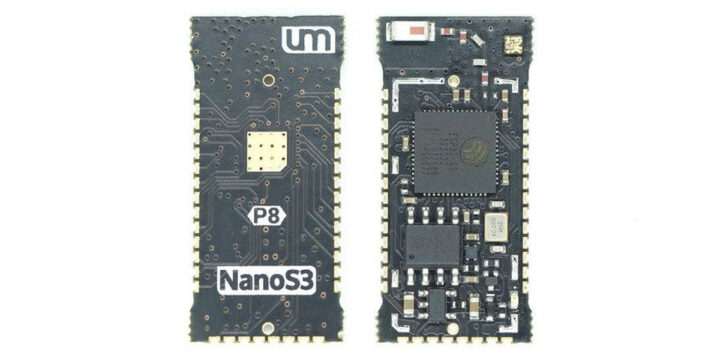

Seon Rozenblum, better known as Unexpected Maker, has launched NANOS3 a development board that claims to be the world’s smallest, fully-featured ESP32-S3 module! This new module packs all the peripherals, and wireless connectivity features of an ESP32-S3 while being even smaller than the TinyPICO Nano. The module features two variants one with an onboard 3D antenna and the other with an u.FL connector. Previously we have written about TinyS3, FeatherS3, and ProS3 boards from Unexpected Maker we have also covered many unique ESP32-S3 boards like the ESP32-S3 PowerFeather Board with solar input, the Waveshare ESP32-S3-Relay-6CH, the ESP32-S3 4G dev boards and more feel free to check those out if you are interested in ESP32 boards with advanced features. Unexpected Maker NANOS3 Specifications ESP32-S3-WROOM-1-N8R2 MCU – ESP32-S3 dual-core Tensilica LX7 up to 240 MHz with 512KB SRAM, 16 KB RTC SRAM Memory – 2MB QSPI PSRAM Storage – 8MB QSPI flash Wireless – [...]

The post Unexpected Maker NANOS3 might be the world’s tiniest ESP32-S3 module, yet fully-featured appeared first on CNX Software - Embedded Systems News.