21

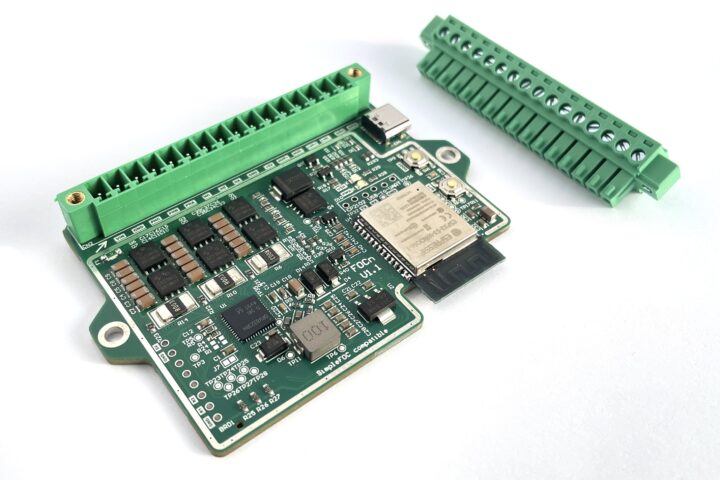

European engineer, Matej Planinšek of PLab, has developed the FOCn — a medium-power BLDC driver module based on ESP32-S3 WiSoC capable of delivering up to 10A of continuous current. It is compatible with the SimpleFOC Arduino library making it easier to control BLDC (brushless direct current) and stepper motors with the field-oriented control algorithm. The developer was inspired to create the FOCn module when their search for a custom-made, SimpleFOC-compatible driver module that met all their requirements failed. The name is related to field-oriented control (FOC) and also means “face slap” in Slovenian, Matej’s native language. The driver module is based on the ESP32-S3 dual-core XTensa LX7 microcontroller which provides Wi-Fi and Bluetooth connectivity. The microcontroller further supports ESP-NOW, a low-power and low-latency communication protocol, which makes it possible for multiple FOCn boards to talk to one another. FOCn driver module specifications: MCU – ESP32-S3 dual-core XTensa LX7 microcontroller @ [...]

The post FOCn ESP32-S3-based, medium-power BLDC driver module supports SimpleFOC appeared first on CNX Software - Embedded Systems News.